BMW AIRHEADS: 4 & 5 speed transmissions

How they work. Shifting smoothly; preloading the shift lever; clutch effects.

Oil types. Break-in. Noises. Rattles. Shift linkage. Neutral switches.

Serial numbers, model year, changes. Pawl spring breakage. Rubber piece

located on the shift lever.

5-speed output shaft snap ring (circlip) & groove.

Bearings.

Shift kits. Input shaft seal. Kickstarter problems.

Throw-out bearings & pushrod.

Gear ratios. Doing It Yourself .....etc.

© Copyright 2024, R. Fleischer Preliminary & Introduction: Many folks have problems understanding, let alone visualizing, how BMW transmissions operate. I am putting some links at the beginning of this article to help with understanding; and, these links also have some information, and photos, on overhauling a transmission. I STRONGLY RECOMMEND you look at all these links! Link #1: From the BMW Factory School on the 5 speed gearbox and both early and late clutches. This article covers the design, parts, how they fit and work, disassembly and assembly, specifications, etc., of the gearbox and the two types of clutches. Link #2: Commentary. http://micapeak.com/bmw-gs/trans.html Link #3: https://www.schweizerschrauber.ch/mot/gearbox.html Overhauling information, with photographs. Link #4: At the end of this paragraph is a link to an article that has vastly more information, and while it does cover some information on how the transmissions operate (4 and 5 speed), there is an emphasis on how and where any wear happens, hints, recommendations, testing, etc. It includes what to watch out for during rebuilding/repairs, and a lot more. Some quite good information on testing & details. The article describes the broken clutch lever pin problems, & you will find the part numbers & information in my

https://bmwmotorcycletech.info/clutch.htm article for your Airhead. Duane's article does not cover a lot of what I do & certainly does not cover all my missing circlip testing, nor how to go about any ideas of overhauling a transmission, shimming it, nor ANYthing about the 17.5° gear angle change, etc. My article is more complete, particularly about 5 speed transmission problems; but, Duane's article has things I do NOT cover. I think Duane's article is nearly a must-read. NOTE that Duane's article covers mostly the /5 and /6 era transmissions, but a lot of the information is applicable to ALL Airhead transmissions, including the /2 era. Transmission ratios for Airheads, 1970-1995.

https://bmwmotorcycletech.info/transmission.htm

59A

https://bmwmotorcycletech.info/Gearbox-and-clutch.pdf

https://w6rec.com/bmw-motorcycle-5-transmission-gearbox-service-and-repair/

Availability, article for beginners and moderately advanced folks, who want to work on their 5 speed transmissions, is a copy of an issue of The Airhead. This contains sketches, lots of details, etc. This is located in Snowbum's personal BMW STUFF folder in his main computer, titled V4-Issue 6.pdf. This is a full copy of the last issue (?) of The Airhead, a publication that was produced for a BMW club in the UK. It is the March, 2019 issue, Volume 4, Issue 6. The 5 speed article is hardly the only thing in this Issue.

I can possibly e-mail this entire Issue. I have never widely published any of my HOW-TO transmission articles, and this issue of The Airhead has some very nice information. You will have to ask me. A contribution to my PayPal account would be appreciated, after you get the E. There are some links in the Issue, too.

Link #4: https://largiader.com/tech/airtrans/ Be sure to look at this article!

Note: if interested in the pre-1970 models, see:

https://bmwmotorcycletech.info/ringgears.htm

Gear

4 speed ratio

5 speed ratio

Comments

1st

3.896

4.400

2nd

2.578

2.860

3rd

1.875

2.070

4th

1.500

1.670

5th

1.500

OIL:

BMW has never wavered in its Airhead motorcycles' transmission oil recommendations, and this includes the first and last of the Airheads. While straight grades are listed in the Owner's Handbook, the only listed multigrade oil is 80W90. BMW did not restrict use of petroleum and synthetic oils, stating only to use a GL5 oil (& that it be a Brand Name ...BMW-speak for "quality").

In the past I recommended you use ONLY a quality petroleum GL5 oil in your Airhead transmission; preferably in grade 80W90 for most conditions. I also said that you could use 75W90, 80W90, or 85W90, depending on weather. There are oils available that replace the "90" with 120 or even 145..... I recommended that you do not use them unless: you live in an area where the temperature that you start the bike at will be ~100°F or more, and that you will be riding fast &/or with heavy loading, or pulling a sidecar or trailer ...all in very hot weather ...that means consistently 100°F or more. There is an exception; some very few transmissions will stiffen-up gear changing when the oil is hot, and different SAE grades can be tried.

My present recommendation is that, if you want to, you can use a synthetic gear oil of good quality. Synthetic gearbox oils are very much improved, hence my changed recommendations. There is no question in my mind that HIGH QUALITY SYNTHETIC GL5-rated oils WILL SIGNIFICANTLY PROLONG the life of a transmission (& rear drive) that does not have previous problems or wrong assembly clearances. In some instances seals & synthetic oils may not be perfectly compatible. If you change from a petroleum to a synthetic, & get some weeping or leaks, change to another type of synthetic, or go back to a petroleum. With the change back to dino oil, the seal(s) are then likely to reshape with some miles & time and stop weeping. Seals have varied in materials over the years, even with the same part number. I recommend that you NOT use any additive if your transmission is filled with synthetic oil. One such additive is made by Dow Corning and sold, $$$$, by bearing sales companies, and must not be used in strength (amount) as stated on the container, in BMW motorcycles. I do not recommend ANY additives except in very special circumstances. For a synthetic oil, I am presently recommending only Spectro brand gear oil, in 75W90 in the version version called "Platinum", for the transmission & the rear drive of Airheads & Classic K bikes. I have no objection to it being used in the driveshaft (of those models using oil there). In fairness, I will also note here that one experienced transmission rebuilder, Tom Cutter, my words here, believes synthetic gear oil in your Airhead is not good, leading to unspecified WEAR. I absolutely think the opposite, but there are instances that I think wear from using a synthetic oil IS going to happen. I have NO objection to Castrol 80W90 GL5 oil in NON-synthetic; NOR do I have any objection to any of Spectro's GL5 rated gear oils, in appropriate SAE viscosities.

Any oil will thin & thicken with temperature changes on 'its own chart curve'. How this happens is a property of the base oils & additives. Using a thicker (higher viscosity) PETROLEUM oil (than the stock 80, 90, or 80W90), ending in 120 or 140 or 145, will take the transmission operation out of the design operating area, as far as gears & parts speeding up & slowing down during shifting due to oil friction, etc, ....>>thus gear changing up & down can be different, and may give problems. Restating this: One difference is in spin up & spin down time for shifting. Gear clashing can be different. I am also concerned that, when colder than approximately 90°F (or maybe somewhat more) air temperature; and/or the engine not being used at high output (which produces more heat, which certainly does get to the transmission, and transmission internal friction also adds heat), lubrication is possibly reduced, protection could be decreased, & there are other not-so-nice things. For example: 80W145. That oil at any normal operating temperature will ALWAYS be thicker than if the oil was any lighter grade, including 80W90. If you wish to think about this in a different way, imagine the oil is rated at 80W20000, & THINK about what that means. Thus, at most any temperature you will be riding at, even after a full warm-up, the oil is thicker, a lot thicker. NOTE ALSO that the thicker oil will have more horsepower losses associated with it ....more friction within the moving oil itself too ....besides the various gears, etc., changing shifting characteristics due to different slow-down and speed-up slowing. The oil may additionally heat up more due to the added friction. So, in general, I highly recommend you do NOT use 80W145 and similar very wide range gearbox and rear drive oils, no matter if synthetic or petroleum.

There is an oil rating called Viscosity Index (VI or v.i.), which is the RATE of thickness change of the oil with temperature change. A straight weight oil, such as SAE 80, will thin much more than a 80W90 as temperature rises. For such as a 80W145, as just one example of oils with a much higher top number; as your parts & oil rise in temperature, the oil thins less, & the specific lubrication qualities of friction inherent in thicker oils, are modified. Note what I mentioned about speed of parts slowing-down or speeding-up being changed from AS DESIGNED. The base stock & the additives control this. BMW wants you to use what it specifies. That's generally a very good idea. BMW's transmission designer/manufacturer, Getrag, specifically designed the transmission to use either straight 80, straight 90, or 80W90 multigrade, all in only GL5. Just in case you were 'guessing' here ...no, the objective here is NOT super high viscosity index. Spacing of parts, spin-down and spin-up times, etc., all change as the transmission heats up; and the oil grade is specified to help match other transmission characteristics. A reasonable VI is assumed, and that is very likely what you will get with the standard oils, and I am not making specific recommendations, besides using Spectro's gear oils.

Better oils are now available, compared to when your bike was made, but 80W90 quality oils rated GL5 are still excellent, although a quality 75W90 may be slightly better, especially for those who ride (or start their rides) in colder temperatures.

NOTE: do NOT try to compare gear oil viscosities with motorcycle or car engine oil viscosities. The oils are NOT tested NOR RATED the same way!

Any oil for use in your vehicles need to be of types that leaves a very thin layer that sticks to the gears & bearings rather than drip completely away during overnight or longer storage. This is particularly so for the 5 speed transmission. You will not be able to easily find out about YOUR PROPOSED OIL, in this regards. This is another reason to use a QUALITY oil which has a good history.

I believe the transmission & rear drive oil should be changed every 10,000 miles; with the synthetics at 15-20,000. I believe it will pay you over the long run to use MY recommended oil change intervals.

HINT: Yearly, remove the forward band clamp on the rubber bellows at the Universal Joint area at the back of the transmission. Use fingers and push back a bit of the forward part of the rubber bellows, and check the tightness (DO NOT loosen first) of the 4 special bolts at the U-Joint. I usually have the transmission in gear, & use the clutch lever to enable rotating the flange to the 4 positions that will be needed (rear wheel is off the ground). Then have a helper if needed to apply the rear brake as you try to tighten the 4 bolts, one by one. Your method can vary. Use the proper adaptor tool, on your torque wrench, and check the 4 special bolts at 25 to 29 footpounds, said torque to be at the bolt itself, so use the torque wrench adaptor at 90 degrees; or, if the adaptor is used straight out, adjust the torque wrench lower, as calculated, to enable the proper 25 to 29 ftlbs.

If there are lockwashers under the 4 bolts, remove, and obtain the proper slightly shorter bolts, do NOT install lockwashers or washers of any type. If you install with clean and dry threads, use 25-29 ftlbs. If you install with one drop of medium strength (blue) Loctite, then tighten to 25 ftlbs. When checking torque in the future, always check tightness, do NOT loosen first. If you install as I recommend, then replacing the bolts at every use is not needed, as they will not have stretched permanently.HINT: If your Airhead transmission is stuck or difficult to shift; perhaps the lever seems somewhat disconnected inside the transmission:

Check the shift lever at the transmission. If it has a Allen screw in its center be SURE that screw is moderately tight because if the screw backs out much, the lever will move & shifting can be difficult, or even not work. Much easier to fix than a broken pawl spring inside the transmission!

Transmission rattling noises (oil hot, idle rpm, transmission in neutral, handlebar clutch lever forward---not pulled back. Motorcycle is stationary):

It is NORMAL for Airheads to have a gearbox rattle noise at idle RPM, with the oil hot from riding. Usually there is no rattle with cold thick transmission oil. Old Airheads were pretty noisy. Worse as various bits & pieces wear. It is usually not indicative of any problem. The rattle typically sounds worse if the carburetors are out of sync, or anything that allows the cylinders to be a bit unbalanced in operation. This includes irregular ignition timing ....rather common on the pre-1979 models, but all Airheads can exhibit the rattle noise. The irregular ignition timing can be seen with an ignition-fired strobe light shining on the timing hole. There will be substantial double images. The rattle will be worse with timing chain sprocket wear, or other associated items, like the chain, guide, etc. Identification: When you pull-in the clutch lever with your left hand, and often if the rpm is raised a bit, the rattle noise will stop. Explanation, etc., follows:

The cam that operates the valves is a jerky load on the timing chain. That can cause irregular power pulses, primarily but not exclusively from irregular ignition timing. A bent cam tip, as on pre-1979 models, even as little as 0.001", can make it worse due to irregular ignition timing & is not unusual. The irregular power pulses cause the engine to not rotate smoothly; that causes jerkiness on parts in the transmission, causing the "Airhead Rattle". The tell-tale sign is that the noise goes totally away when you pull-in the clutch lever at the handlebars & also typically tends to go away if you raise the idle rpm some with the throttle, clutch lever not pulled-in.

Do not have the engine idling too slow. Some books may show as low as 800 rpm. Back in the old days of heavy flywheels, especially on models prior to 1970, it was common for folks to brag about how smooth & silent their engine was at idle. Unfortunately, trying to idle the engine so low (many would try for 500 or 600 rpm, let alone 800), is BAD for the engine; particularly a worn engine. I suggest 900-1025 rpm for all models from 1970, and 850 for prior models.

If the idle RPM is too slow, oiling (lubrication and cooling) to the timing chain & sprockets will likely be low enough to accelerate wear on those items. This is worse with an older worn engine. The only oil these parts get on an Airhead is from the relief hole in the oil pressure regulator. If the oil is hot & thin & idle rpm is low, then oil pressure is low, & there is no or much less oiling.

Airhead rattle is LESS likely and less noisy, on models from 1979 due to the improved ignition stability (cam drive to the ignition is much improved), and even slightly better from 1981, and the somewhat better chain tautness control; at least early-on, but DOES deteriorate with increasing miles.

Transmission problems, checks, testing:

Drain the transmission oil after a ride. You can wait until the oil is warm and not hot. Put #1 eyeball on the magnetic drain plug. If there is anything more than a modest amount of soft fuzz felt between your fingers, then there is a problem. NO SHARP PARTICLES NOR PIECES should be felt. If there is anything small & sharp, you may (or may not!) be safe for a reasonable amount of riding to where the transmission can be opened. Anything large? ....take an in-focus close-up photo, post it in at a free hosting site on the Internet, then inquire on the AIRHEADS LIST, with a link to the photo.

Four common things that are not usually a transmission-failing problem:

(1) Small/modest amounts of 'fuzz' on the magnetic drain plug, seen at every scheduled 10Kmi gear oil change. The fuzz will NOT have sharp particles, not feel like sand. The fuzz is paste-like, & smooth feeling.

(2) Rattling noise from gearbox in neutral, at idle rpm, after thorough warm-up, clutch lever not pulled in at the handlebars. Noise disappears with handle bars clutch lever pulled rearwards.

(3) Mild to moderate shifting problems, especially from 2nd gear downward to 1st. This usually means that your input splines need lubrication. Unplated early input splines usually need cleaning & lubrication at 12,000 to 20,000 mile intervals, nickel plated shafts at maybe 20,000 to 35,000 mile intervals ....depending on riding conditions, number of heat/cool cycles, time (in years?) & type of gear oil used. I recommend 12,000 to 20,000 mile checks. If at all rusty, lower the mileage between servicing.

(4) Shifts not always made. Check the allen screw in the shift arm (if you have that type with the screw in the middle) ...they are known to loosen. Use a dab of Loctite blue on those screw threads. Perhaps your boot tips are overly thick ....reset the linkage, or adjust the footpeg.

If you have a sudden vibration while riding, and possibly noises (or not), and the vibration ceases (or does not!) when the clutch is pulled in while riding and throttle turned off ...and ...you can also try in the various gears, and in neutral, ......This is the time to stop and investigate what is going on, as best you can. If it is not something with the wheels/tires, etc., and the noise is present with the bike not going down the road, have the bike towed. Failure to comply will likely, within a few miles, lead to a massive failure. I can not emphasize this enough...stop riding, now ...not in 50 miles ...otherwise, it can cost you a bunch more money; and, you risk the rear of the motorcycle locking-up.

NOTE! A considerable amount of this article deals with the no-circlip problem. Be aware that the 5th gear bearing on the 5 speed gearboxes can fail, even if there IS a circlip. If you hear noises from the gearbox, and have metal particles on the magnetic drainplug, you really need to stop riding and look into the situation, as the longer you ride using a noisy gearbox, the higher the $ cost to repair it, and, eventually, the gearbox could even lock-up, etc.

If you do regular checks on the magnetic drain plug (what? ...you don't have a magnetic one?) ....you are much less likely to have such sudden problems. These regular checks really should be done often if your Airhead motorcycle is model year 1984 to 1995. While the problem is unlikely for 1984 and prior models, I am including them here. If you know ...by the transmission having been apart! ...that you have the circlip, you probably will have no need to check the magnetic drain plug except at regular gear oil changes (10Kmi)....unless you start having NOISES!

These links are to the BMW Service Information bulletin about the transmission circlip. This SI is here only for you to more visualize the problem area...do NOT use these for actual work, until you have carefully read all that is in the article you are reading:

If your transmission is in the range of the ones possibly not having the circlip (detailed information later in this article, but, basically, late 1984 to 1995), you might consider an overhaul well before you have a failure, as the number of $$ parts to be replaced always greatly increases as you accumulate mileage. If you watch the transmission as FULLY outlined, you can consider NOT doing a preventative overhaul.

Even if you hear & feel nothing peculiar; every few thousand miles, put the bike on the center-stand, when the engine & transmission are thoroughly warmed up from a ride. With engine off, and transmission in neutral, spin the rear wheel & listen for growly sounds. Turn the wheel slowly & feel for notchiness. When the engine & transmission have cooled overnight, check the magnetic drain plug. GENERALLY the degradation is slow, but sometimes it does come on suddenly, with noises and/or vibration. Some remove the drain plug; and instead of draining and replacing the oil, they have a rubber or cork plug, so the drain plug can be inspected and replaced with very little oil loss. Others check the magnetic plug only at normal transmission oil change time (10,000 miles). It is up to YOU.

BMW, like most manufacturing companies, is tight-lipped regarding engineering details/changes. BMW tends to be more tight-lipped than many companies, probably from both a corporate policy & the Germanic 'WE don't have problems'. BMW may issue Service Bulletins of various sorts now & then, but these often do NOT spell out details that one might like to have, & sometimes what is said is confusing, especially considering what is NOT said. We have to live with that. Sometimes some of us 'Wrenches' manage to "get information". In some instances I have been given information that might be considered Company Top Secret. I can NOT divulge in such circumstances my source(s) ...BUT!!.....one way or the other, in almost every instance, I DO manage to get the information to you.

DETAILED (more) TESTING:

What are some other checks & tests you can do to determine if your 5 speed transmission has a problem developing?

(1) AFTER a 20+ mile ride to THOROUGHLY warm up the engine & transmission; on an appropriate stretch of road, in 5th gear, at maybe 5500 rpm (if possible, because that is FAST!), suddenly whack the throttle wide open. 5th & 5500 is such a high speed, so you may have to test at lower rpm. If you feel some vibration that is unusual, for SURE you will want to do all the tests below, and other places in this article ....as the forward bearing on the output shaft may be disintegrating.

(2A) With a warm/hot gearbox, whether or not test (1) shows anything, jack or otherwise raise the rear wheel so it is slightly off the ground. With engine off, in neutral, spin the rear wheel by hand fairly fast & listen to the gearbox. This spins the output shaft bearings only. No bearing noises should be heard. Now, rotate the rear wheel forward slowly. No roughness & no notchiness should be felt. These two tests are best done with transmission quite hot from riding. These tests tend to also show up a bad bearing caused by allowing water to get into the transmission, usually from over-vigorous spraying during washing (at the hollow speedometer cable bolt), or from a bad speedometer cable rubber boot (very common problem; both water problems can lead to $$$ repairs). There is a fair amount to know about this speedometer cable boot area. Please see the complete write-up in article 7B (~half-way down), the control cables article. I highly recommend making sure that your speedometer cable boot fits snugly, & is sealed at the top with silicone RTV. If the top is poor, water can run down into the transmission, causing $$$ damage. Milky (coffee with cream) look to transmission oil is very bad ...it destroys bearings.

(2B) This is an additional test THAT SHOULD BE DONE. You will need an inexpensive mechanic's stethoscope. The best test is with standard 80W90 or 75W90 transmission oil. The motorcycle needs to be ridden enough so the transmission oil is hot. As soon as you get back from your ride (maybe 20 miles, but twice that is better), immediately put the motorcycle on its center-stand. You should have determined before the ride how to block the rear wheel safely off the ground, because you are going to be running the engine, transmission in both 4th and 5th gear, and rear wheel turning rather fast. Because of these things, there is no way to 100% safely do this test without a buddy helping (although plenty of folks have followed my directions and done it without problems, sans buddy). With the engine restarted (remember, the transmission oil must be hot from your ride), put the transmission into 4th gear and ~3000 rpm. Listen to the transmission using the stethoscope. The stethoscope rod should be touching the top of the transmission on the right side, forward. Change to 5th gear and 5000 rpm, listen again. Go back to 4th, then 5th. What you hear should be reasonably close to being the same, comparing both gears. If things are very much worse in 5th gear, then the front output shaft bearing is failing. This is a very definitive test.

(3) Re-start the engine (with already hot engine & hot transmission) & let it idle in neutral. Pull in the clutch lever for a few seconds & then let it out. When the clutch then re-engages, this spins the input shaft & cluster shaft bearings only. There should not be a bunch of bearing noise(s) when you let the clutch lever out (you may hear some normal clutch spline chatter and transmission rattles).

(4) If the slightest suspicion, or just because you want to be very cautious, I recommend you unbolt the driveshaft Universal Joint from the output flange of the transmission; &, in neutral, rotate that transmission flange with your fingers. Any roughness or notchy feeling is cause for the transmission to be overhauled. This test can be used to show up bad driveshaft u-joints on the Paralever models, & disconnecting the U-joint at the transmission output flange, & rotating first the transmission flange and then the U-joint, will, or may, allow a yes or no on U-joint & transmission.

Note! The U-joint at the transmission output on any Airhead model can be a bit stiff, especially if cold, and still be perfectly OK.

(5) This test is best done by screwing at least two opposing bolts into the flange, just to provide something to grab onto. Try to move the flange in and out. Any free play is likely caused by internal problems.

(6) The transmission output flange has 4 special bolts; they are not to be used with any type of lockwasher, contrary to old literature or what you may be told. The thread length of the latest & proper bolts is slightly shorter. Split-lockwashers & longer bolts should be removed, if present. There is information on this website about this: https://bmwmotorcycletech.info/drvshftboltstoolstorque.htm

The threads of both the flange and the 4 bolts should be cleaned, and not oily. Apply one drop of Loctite blue (medium strength). Tighten in a cross-pattern to 25 or 26 foot pounds. There are various methods of enabling use of a torque wrench at this place. You can also just give the bolts a good grunt with a short 12 point wrench. It is best to torque them properly. See prior link, and also https://bmwmotorcycletech.info/tools.htm

The above tests are important. Usually any problem reveals itself, even if there is nothing much on the magnetic drain plug.

(7) Please scan way down this article, and read the following section (or, just click on this link) (or, read it later):

MORE DISCUSSION

The Circlip problem applies to many 5 speed transmission from calendar year 1984 to the last of Airhead production in 1995/1996, including the R80R and R100R, Mystic, etc.

THE PREVENTION of damage caused by movement of the forward-most gear on the output shaft is not 100.00% guaranteed by adding the circlip; but you can expect that, if properly done, it will be a permanent fix, in nearly all instances. Contact your favorite transmission overhauler about their personal method of ensuring that the gear does not move or have a problem with the circlip or wire spacer, etc: Tom Cutter, Ted Porter, Bob Clement, etc.

A link to a 5-1/2 minute video by Ted Porter. Many folks comprehend better with visual presentations; after which they are ready for the in-depth explanation. |

| http://largiader.com/articles/circlip/ is one of two transmission articles on Anton Largiader's website that you will find of interest. http://largiader.com/ is his HomePage. Anton has two articles to look at, possibly not overly clearly shown as being two different links, so look on the left side list of articles. Put mousepointer over "transmission" in "Airhead transmissions and circlip problem". The word 'transmission' will then be seen to be a link to one article. Click on the word. When finished looking at that article, go back to Anton's HomePage again and this time put the mouse pointer over "circlip problem" and click for the other article. |

OVERVIEW of the circlip problems (vastly more information later):

From sometime in the late 1983 production year for 1984 calendar year Airheads, BMW's transmission maker, Getrag, made a modification to the transmission. Not all transmissions had this modification, particularly not so, or unlikely, with the early 1984 models. As time went on, more and more transmissions had the modification.

On the output shaft, Getrag left out a snap ring (circlip) & shortly thereafter (?) they no longer even machined a groove for that snap ring into the associated output shaft. The no-circlip modification has caused a lot of grief. Years later the design supposedly reverted back to the original reliable version with a circlip, the exact date of which is not truly known, and BMW's own information seems in error. BMW's explanation of why that change-back is corporate lawyer-ezz nonsense, IMO. Note that, trying to be 'somewhat' more fair to BMW here, some very few transmissions with a circlip have had problems with the 5th gear moving a bit.

Note that BMW's information regarding the transmission serial number at which the change was made back to a circlip is not accurate. You can not trust the serial numbers.

A substantial number of 'circlipless' transmissions have failed, some catastrophically ripped the transmission to pieces. Transmissions seldom fail without warning. Most transmissions do not fail. Interestingly (?), quite a few have been taken apart, at fairly high mileages, found to have the circlip, & no problems; but, in others, with no problems seen or felt by the rider, there have been some movement of the circlip & bearing, but bad damage had not yet occurred. It is my belief that if your transmission does not have the circlip, you're vastly more likely to have problems.

| Many years ago there was not 100% agreement on the exact mode & reason for the failures of circlip-less transmissions. I have not seen anyone espouse the main minority opinion for some time now. I still have the two basic opinions later in the below article. AFAIK, the circlip information first appeared relatively widespread in a 2001 Airheads LIST posting by Bob Clement of BMW-Montana, who gave me permission then to post his correspondence with me, which I did the majority of, on that LIST. In the below article I have added comments from private communications from several transmission experts, & you also get my own verbose input. ...and, as noted, the two different ideas & opinions about the circlips is included. |

This is not so easy, not so cut & dried; there simply is no perfect method of determination for the earliest transmissions without taking them apart! If we had specific information with every serial number for every transmission that Getrag made for BMW, that would probably do fine. None such has ever been released to even BMW dealerships, AFAIK. A BMW bulletin in 1986 gave no specifics on year & transmission serial number. There was no change in part number for the output shaft. BMW is known to sometimes make a production part change and to use the same part number. It appears that the earliest transmissions that were affected were shipped with motorcycles of build date near the end of 1984, so that means that some late 1984 models may not have the circlip. Since I often have requested transmission overhaul information on the Airheads LIST, ETC., I refer you to the charting/listing I have later in this article; you will see the 1984 year status. Take a look at the 1994-1995 information too.

There was another, later, factory bulletin, #280, dated 12/08/97, explaining that the circlip (& therefore the groove) was reinstated, & the shaft number was changed. However, it appears that the shaft is actually the same as the 5 speed output shafts built from 1974 into 1984. The specified 'new' shaft is 23-21-1-338-793. BMW raised the price of this shaft tremendously.

One can, & competent transmission overhaulers do, modify the non-circlip shaft, but this needs to be done very carefully. It can not be done if the gear mounting area has noticeable taper wear from the gear wobbling. The bulletin also mentioned a 'special bearing' for the front of the output shaft. There is some controversy about this, and this bearing was made by a Japanese bearing manufacturer. More later herein.

Transmissions beginning with serial 240765 supposedly had the circlip re-installed. Do not depend on BMW's bulletin information using that serial number!!

It is my strong belief that you cannot depend on even a 1995 bike as having the circlip. See my list of reported transmissions, much later in this article. You also cannot depend on any 1984 to have, or not have, the circlip. Still, the best information, if your transmission isn't being taken apart, will be had by testing as I have outlined; and, looking at the transmission serial number. Even that is sometimes questionable, if you look at the charting later on this page. However, it seems likely that most 1984 transmissions are going to be OK. It presently appears that 1995 is going to be mixed, with most (?) being OK.

Summing-up, to this point in this article:

It is possible for a transmission built from 1984 (& possibly somewhat earlier, perhaps late 1983), & certainly from 1985, until even after transmission serial number 240765, to not have the circlip and possibly the shaft has or has not a groove for the circlip. I have had reports of transmissions after 240765 as not having the groove nor the circlip! Any I have definitive information on are listed well below. Thus, BMW's use, in BMW bulletins, of 240765, is not to be relied upon.

Transmission serial numbers are found in one of three places. Early transmissions, from 1974 to 1981 (or, I believe, as late as late 1983, depending on country the motorcycle was shipped to), will have the serial number on the top rear center or top front center, where you can not see it without removing the air cleaner assembly. In 1978 (& until the serials were put on the left outside, in approximately 1984), the serial was on the front inside face of the casting. Thereafter, the serial number is located at the top area of the left side, just barely below where the left rectangular airbox outlet hose connects; so you have to squat down to see it. Serials are stamped into the aluminum transmission case. There are some variances so noted below.

When reading in this article about 'year', be advised that BMW's 'model year' includes motorcycles that were built near the end of the prior calendar year, & it is quite possible to see a build date as early as the beginning of September, to be included in the following year's models ...and, there is occasionally an anomaly & an even earlier than September-made model will be dated in the following calendar year; which I suspect was from there being motorcycles on the production line at the time the company vacation began. BMW closes the company for the annual month-long holiday (vacation) which is in August. A September, October, November, & December production almost always will be the next calendar year's bike.

1974: Serial numbers ranged from Y-4300 -> Y20050; after which the numbers continued without the Y letter. Serial numbers are located at top rear, at center of case.

1975: Information sketchy, some end of 1974 transmissions probably used, may have Y prefixes; otherwise no Y. Numbers from 4225 -> 13500 have been identified, without the Y prefix. Serial number same place as 1974.

1977: Some from 1976 used, so one can expect serial numbers from 46000 to 63000. Serial numbers either at top rear center or top front center, in front portion of casting.

1978: 72400 -> 83000, and after those had a prefix letter Z which may have been early 1979 transmissions made in late 1978, as Z-0870 -> Z-0940. Serials are now on the front inside face of the casting. The 1978 transmissions had gusset reinforcement running only from front to rear (none left-right).

1979: All have Z number prefix, from Z-19100 -> Z-36750 (at least).

Beginning in 79 the gusset reinforcements at the bottom of the case were cross hatch like a crossword puzzle. Changed was the shift linkage. It now pivoted from the footrest, & was more positive. 1979+ transmission cases were RIBBED. This ribbing makes the cases stiffer, preventing, mostly, any change in shimming dimensions with high mileage, etc.

Note: BMW has had fun & games with transmission serial numbers. It is possible that early transmissions with kickstarters have ZSA serials, for one example.

1980: The Z number now begins with a zero: Z-052800 -> Z-064950

From 1981, for awhile, at least to 1982, things get confused, with serial numbers lower.

1981: There are some numbers that seem to fall in the 1980 group, but the casting is different. Most will find that the serial number is now on the left exterior side, top rear. Expect serial numbers of Z-006111 -> Z-029900. Z & ZSA models in Europe, & maybe some to the USA, from s/n 56476 have the shift kit, & from same with s/n 58225 have the 17.5° change to the helical gears.

Note that the leading zero may not be present.

Oak told me that some 1981 castings for engines or transmissions had incorrect dimensions, which could cause perpetual failures of the input shaft of the transmission. There is no fix for that, I think. I have no information (just suspicions!) about whether or not this could also be the cause for the quite rare instances of continuing spline failures of the clutch friction disc.

In mid or later 1981 (this is unclear to me, although the serial number of the transmission is known, see just above and just below), & probably happened fully by mid-1982, BMW installed the so-called 'shift kit' inside the transmission. This is a fairly extensive kit with a revised cam shape, modified shifter arm, etc. It is retrofitable, & can be considered for earlier transmissions when overhauled, but it makes only a slight difference in the heavy flywheel models. BMW has a habit of phasing in changes, sometimes on some models long before others ...and on occasion one might find a far later serial number without the shift kit change; & transmissions with partial changes. As has been noted well above, the 1984+ transmissions had the transmission serial number on the left outside, just under the air-box fitting surface (just below the air tube to the left carburetor). Earlier transmissions had the serial number at either the rear top, or front top, but you must pull the air-box to see the number. You will do that at the spline service anyway. The serial number for the beginning of the shift kit installation is: 56477 (some sources, including BMW SI, say from 56476). The prefix was Z or ZSA. Yes, this information seems to conflict with the charting of transmission numbers here!

1982: Z-036600 -> Z-060400.

1983: Z-074700 -> Z-084299. Beginning in very late 1983, or possibly in early 1984, the serial number is then located on the left side, just below the air-cleaner outlet to the left carburetor.

1984: Z-084339 -> Z-104600 Transmissions well above that number have been seen, and positively identified as true 1984 model and calendar year motorcycles.

1985: Z-113701 -> Z-130150. Many transmissions lower than Z113701 have been reported on 1985 model year motorcycles.

1986: ZSA-125500 -> Z-125600. No other data has been provided, nor accumulated, for 1986. Obviously, there were more than 100 motorcycles made. See the charting of transmissions by VIN and transmission serial numbers, for 1986, later in this article.

Note: BMW seems to be using, at least a fair amount of time, the letters ZSA for kickstart transmissions.

1987: Unknown, but it appears that most after Z-125600 were produced after the return from the company 1986 vacation, and thus should be 1987 models, but are anomalies, see the information later in this article, by years.

1988: Z letter is dropped (tentative information for date this happened). From whatever time in 1988, serial numbers all now have a 3 letter suffix. Expect numbers from 0147440. AAB -> 0164300AAI. Suffix's may, however, be AAB, AAI, AAJ, ETC.

1989: 0154140 -> 0176330 and suffix (note from snowbum: I am sure that the serials go higher in the 0176xxx)

1990: 0180939 and suffix. Have not collected any further information on factory listing of supposed s/n range.

1991: 0190460 -> 0198650, and suffix. For sure some were built in mid-year (not after the Vacation) that had even higher serial numbers.

1992: 0207050 -> 0215650, and suffix.

1993: 0204190 -> 0230075, and suffix. I am certain some later serial numbers were 1993 and 1994 models.

1994: 0237930 -> 0238660, and suffix. There were some 1994 models built in 1993, that had lower transmission numbers.

1995: 0236539 -> 0254340, and suffix. NOTE that bikes have been built with end of 1995 dates, and I think into 1996 a bit, for Authorities. Details are not clear. Note the overlap into 1994 serials.

A close look at the serial numbers range of the transmissions for any given year may confuse you. The answer is that BMW did not always sequence numbering for transmissions, depending on the model, and what country it was going to. Thus, the listing for transmission numbers is only approximate. Some transmissions, by their serial number, may have been put into motorcycles identified by VIN numbers as from a full year, even in rare instances more than a year, out of the irregular sequence, above. Example: your bike is a late mfr'd 1991; has a transmission serial of 0204xxx plus some 3 character suffix noted in the 1988+ year, above. Transmission use by serial number is quite confusing at times, and is often model specific. Look at 1992 and 1993 above, and then 1995. Suffixes can also look like this: AA1; AAB; etc.

5-speed transmissions; Circlip/Groove tabulation; reports from owners & overhaulers:

For many years, I have been collecting information on Airhead motorcycles that were known, by disassembly, to be circlip-less five-speed transmissions ....and some reported on that were found with circlips. I tried to select for this article those transmissions that were likely never opened previously for repairs; obviously, that is not going to be 100% perfect, but there ARE telltale signs that are often quite usable. In a few instances I have added information to the charting of transmissions WITH the groove & circlip, where such information may be helpful. Information received, after I independently confirm the VIN, serial number, year, month of production, may be posted to this article in this section, always without identifying the owner's or overhauler's name. Some few transmission reports are not usable and I qA unable to get the needed information. In some instances the information I have received is not useful, or not pertinent, so I have not included that motorcycle nor transmission.

| I want to receive only information on 1983-1985; & 1990-1995 (and 1996 if you have one of those very rare ones) transmissions, both with & without circlips, as found. If no circlip, I want to know if the shaft was grooved, or not. I want to complete my tabulation and fully identify, if possible, earliest & last date of bikes with such transmissions. Please provide full VIN number & full transmission number, & any pertinent information, such as if the transmission was ever opened before. If no 17 character VIN number, please provide what information you can, from right side frame stamping, dipstick area serial number (if present), and information stamped into the milled boss area below-forward of left cylinder. As much information as possible is requested. Information published in this transmission article does not identify you. https://bmwmotorcycletech.info/emailimage.htm |

Reports:

There have been no motorcycles reported to me that were built in calendar year 1983, that had NO circlip.

1983-1984 motorcycles:

This section, for 1983-1984, was done separately, as I felt it was quite important to try to identify any transmission serial numbers and VIN or other vehicle numbers, to see what the earliest no-circlip models might be.

a. R100RT, USA model, transmission Z094331, VIN WB1044904E6243388. This bike was reported to me as having the circlip (& the wire clip located at it). The E in the VIN shows it to be a 1984 USA model, but, the serial number, 6243388, shows it was built June 15th, 1983. This dating anomaly is not uncommon for 1983-1984 bikes.

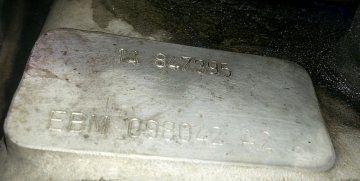

b. R80RT, 1984 USA model. Had the groove, did not have the circlip. This transmission definitely had never been opened. Transmission Z105671, VIN WB1044802E6173763, production 03/1984. The left side engine boss shows: 14 847395. Thus, this engine/bike was made in the 14th week of 1984. This goes right along with the BMW internal information of the motorcycle being built in March 1984, & the serial of the production is 7395. All this seems to be reasonable. Note that other characteristics of this motorcycle back up its production dates, such as not having dipstick area serial stamping, a driveshaft tag with the E year same as the stamped VIN.

c. R80RT, 1984 USA model, Canadian options. HAD groove, HAD circlip. Transmission with kickstart, ZSA 098774, VIN WB1044807E6173502. From the milled boss, engine was done in 47th week of 1983. The week and year stamping was year first, week next, shown as 83 4704 39. This is one of the anomalies. The serial number of bike identified it as being built the 46th week of 1983, not 47th. At the present moment, the conclusion MAY be that sometime after the factory returned from the August 1983 vacation, date unknown yet, maybe December of 1984 or later, the leaving off of the circlip began. This is not fully confirmed yet.

d. R100/T, version is USA R100CS last edition. VIN WB1043502E6177343. Transmission Z105851. This transmission was likely opened previously, perhaps for a broken pawl spring. This transmission was found to have the groove, but NO circlip. The production was confirmed in several ways. The E means 1984 year. I confirmed that this vehicle was dated 3-01-1984.

e. This is another 1984 bike I know about. I have been unable to confirm that the transmission had never been opened up, but believe that is true. This is an Australian bike. The milled-boss area shows 33 845294, meaning the 33rd week of 1984. This agrees with the vehicle identification number stamped into the right lower frame tube: 6354483R65LS (yes, not a 17 character VIN). It also agrees with the Australian Compliance Plate (which was not riveted over that frame tube stamping just noted ...it was riveted ahead of it ....so both could be seen. The plate said R65LS and 6354483. The transmission number is Z 108683. Had groove, but no circlip. BMW sources confirmed a build of 08/1984, ECE (Euro) model. Note, another number that was on the bike: 33845294652VB.

CONCLUSION (with the limited number of above 1983 and 1984 reports), TENTATIVELY, the actual changeover probably occurred with the resumption of production JUST AFTER the August BMW Vacation.By year listings:

If no details are shown assume that the transmission had NO circlip when opened-up. If a full date of mfr is shown, it is in USA standard format: MONTH, DAY if known, YEAR. If a full date of mfr is shown, it is in USA standard format: MONTH, DAY, YEAR.

1985 R80 USA, transmission Z111812, VIN WB1046307F6480009, production 12/1984, no circlip, but shaft had groove, original owner, never been apart before.

1985 R80, transmission Z111168, serial 6440490, production 12/1984, no circlip, but shaft had groove.

1985 R80RT, transmission Z112553, VIN WB1046408F6490109, production 01/1985; series code 2472, no circlip, but shaft had the groove.

1985 R80GS, transmission ZSA 11260, serial 6363139, production 02/1985; series code 2471, no circlip, but shaft had the groove.

1985 R80RT, transmission Z113701, VIN WB1046401F6490338, production 2/1985.

1985 R80, transmission Z115902, VIN WB104630XF6480439, production 3/1985.

1985 R80RT, transmission Z114405, VIN WB1046400F6490413, production 2/1985, no circlip, no groove.

1985 R80, transmission Z114317, VIN ending in 6480354, production 2/1985, no circlip, no groove, transmission known to have never been opened previously.

1986 R80, transmission Z122275, VIN WB1046307G6480545, production Sept 5th, 1985, no circlip.

1986 R65, transmission Z127619, ECE (Australian model bike). NO circlip, NO groove, production 12/85.

1986 R80GS, transmission ZSA124393, VIN WB1034805G6363255, production 10/85.

1986 R65, transmission Z123469, VIN........................6128105, production 9/1985.

1986 R80, USA model, transmission Z124295, VIN WB1046306G6480598, production 10/04/1985, NO circlip; virgin unopened transmission.

1986 R80, transmission Z125576, VIN WB1046303G6480655, production 10/1985.

1986 R80GS, transmission # unknown, VIN WB1034801G6363284, production 10/1985.

1986 R80GS, USA model, transmission ZA126409 (with kickstarter as shipped from factory), VIN WB1034802G6363343, produced 11/25/1985.

1986 R80, transmission Z128362, VIN WB104630XG6480782, production 12/1985.

1986 R80, USA, transmission Z135754, VIN WB1046301H6480851, production 07/1986, yet has H identification which makes it a 1987 model. This bike was a California model, ordered by distributor (?) with two front discs.

1987 R80RT, transmission Z138188, VIN WB1046407H6491304, production 10/1986.

1987 R80 USA, transmission 0144961AAB, VIN WB1046304H6481119, production 05/1987.

1987 R80, transmission 0138910AAB, VIN WB1046301H6481093, production 11/1986.

1988 R100GS, transmission 0151096AAI, VIN WB104780XJ6152090, production 11/1987.

1988 R100GS, transmission 0155023AAI, VIN WB104780XJ6152610, production 02/1988.

1988 R100GS, transmission 0154855AAI, VIN WB1047801J6152611, production 02/1988.

1988 R100GS, transmission 0156870AAI, VIN WB1047803J6152688, production 03/1988.

1988 R100GS, transmission 0155282AAi, VIN WB1047304J6277710, production 02/1988, NO circlip, NO groove.

1988 R80 monolever, transmission 0161951AAB, bike serial number 6448037, production 09/1988.

1988 R100RS, USA model, transmission 0154894AAB, VIN WB1046600J6247481, production 02/1988.

1988 R100RT, USA model, transmission 0162792AAB, VIN WB1046907K6293354, production 10/1988.

1989 R100GS, transmission 0163629AAI, VIN WB1047809K6153197, production 10/1988.

1989 R100GS, transmission 0164105AAI, VIN WB1047302K6332169, production 11/1988.

1989 R100PD, transmission 0171806AA1, VIN WB1047905L6134016, production 06/1989.

1989 R80GS, transmission 0176603AAI, frame serial 6249769, production 11/89. No circlip, NO groove.

1990 R100RT, transmission 0180939AAB, VIN WB1046902L6293473, production 04/1990.

1990 R100GSPD, transmission 0174962AA1, VIN WB1047902L6134300, production 09/1989, no circlip, no groove.

1990 R100GSPD, transmission 0174086AA1, VIN WB1047901L6134207, production 07/1989 (anomaly date), no groove, no circlip.

1990 R100GS, transmission 0179717AAI, no groove.

1991 R100RT, transmission 0185431AAB, VIN WB1046908M6293561, production 08/1990.

1991 R100RT, transmission 0191171AAB, VIN WB1046909M6293598, production 01/1991, model code 0469, USA, no circlip, no groove.

1991 R100GS, transmission 0191372AA1, VIN WB 1048802M0230178, production 01/1991, model code 0488, USA, no groove, no circlip.

1991 R100GS, transmission 01292165AA1, VIN WB1048803M0230223, production 02/1991.

1991 (reported). R100R, transmission 0204599 AAI, VIN WB1048707N0280111, production 10/1991, actually a 1992 model, per VIN.

1992 R100GS, transmission 0198991AA1, VIN WB1048808N0230445, production of 07/1991 (officially ID'd as a 1992 model by the VIN, etc.). NO groove, and hence no circlip.

1992 R100R, transmission 0204810AA1, VIN WB1048701N0280119, production of 10/15/1991, no groove, and hence no circlip.

1992 R100R, transmission 0204181AAI, VIN WB1048706N0280049, production 10/1991.

1992 R100GS, transmission , VIN WB1048803N0230711, production 10/1991.

1992 R100GS, transmission 0205604AA1, VIN WB1048800N0230763, production 10/91, USA model, vehicle code 0488, no clip, no groove.

1992 R100GS/PD, transmission 0209970AA1, VIN WB1048909N0047487, production 01/1992.

1992 R100 (R91)(R100R), transmission 0209230AA1, VIN WB1048709N0280269, production 01/1992, USA model, vehicle code 0487, no clip, no groove.

1993 R100GS, transmission 0210818AA1, no groove and no rear cover gasket (sealant used)

1993 R100RT, USA, transmission 0221583AAB, VIN WB1046903P6293892, no circlip, no groove, production 09/08/1992.

1993 R100GS, transmission 022756AA1, VIN WB1048801P0231259, production 09/1992.

1993 R100GS, transmission 0224420AA1, VIN WB1048804P0231319, production 10/1992.

1993 R100GS, transmission 0226691AA1, VIN WB1048304P6467330, production 12/1992.

1993 R100GS, transmission 0228652AAJ, VIN .....646450, production 01/1993.

1993 R100GS-PD, EURO, transmission 0232033AAJ, VIN 0069483, no circlip, no groove, production 04/01/1993.

1994 R100R, transmission 0234197AA1, VIN WB1048705R0280808, production October 27, 1993.

1994 R80R-R91, ECE model, transmission 0238143AAI, serial number 0263257, production 12/1993, no groove.

1994 R100RT, USA model, transmission 0236278AAB, VIN WB1046904R6294018, production 09/03/1994. No groove, & no circlip of course. I believe the actual production was probably 09/03/1993.

1994 R100RT, USA Model, transmission 0236280AAB, VIN WB1046906R6294019, production 09/1993. NO circlip and NO groove.

1994 R100R, transmission 0236159AAI, VIN WB1048708R0280799, production 09/10/1993, USA model. Preventative maintenance was done at 80K miles, gearbox never previously opened, no problems with gearbox. NO circlip, NO groove.

1994 R100R, transmission 023696AA1, VIN WB1048709R0280858, production 01/1994.

1994 R100R, transmission 238655AA1 no details furnished.

1994 R100GSPD, transmission 0238596AAJ, VIN WB1048408R0340374, production 01/1994 ECE model, no groove.

1994 R100GS, transmission 0237931AA1, lug stamped NI.

1994 R100GS, transmission 0238984AA1, VIN WB1048805R0231610, production 01/1994, no groove.

1994 R100GS, transmission 0238225AA1, VIN WB1048801R0231538, production 01/1994, USA model, no groove.

1994 R100R Mystic, USA model, VIN WB1049705S0400201, had clip & groove. Production 09/28/1994. Transmission number unknown, never reported to me. S indicates an official 1995 model.

1994 R100M, transmission 0240810AA1, had circlip. VIN not reported, 1994 assumed.

1995 R100GSPD, transmission 0246168AAI, VIN WB104890XS0048207, production 01/05/1995, USA model. Purchased new. Had circlip.

1995 R100GS, transmission 0243394AA1 & stamped N1, VIN WB1048802S0231635. Production 07/21/1994. Transmission had higher number than 240765, yet had no groove, no circlip. This is another of the many anomalies, this one being produced before the factory yearly vacation in the prior year.

1995 R100GSPD, transmission 0244317AAI, VIN WB1048905S0048177, production 09/1994, type 0489, had circlip.

1995 R100RT, USA model, transmission 0243572, VIN WB1046902S6294248, production 08/31/1994, transmission DID have the circlip. Virgin unopened transmission.

1995 R100GS; transmission 0243880AA1, owner had it since brand-new. California model. VIN WB1048801S0231688. Produced 09-13-1994. Transmission was overhauled, & noted as having the circlip (so, of course, had the groove for it).

1995 R100R Classic, Euro version (also known as R100-R91), serial 6469362, production 04/1995, with transmission 0249173AAI. Had groove, had circlip, was original, never previously opened.

The following is the highest transmission number reported to me, so far with no circlip. 1995 R100M (Mystic), transmission 0251758AA1, VIN WB1049706S0400255, production 09/12/1995, had no groove, no circlip.

As you can see from the collected information, it is not easy to determine if a bike's transmission has a circlip, or not, from model, year, serial number of transmission, nor VIN or other ID number. Note some of the strangeness of the 1995 models, above. Compare to earlier years too. Note that some 1995 production bikes, after the BMW bulletin's official number for reinstatement, still had no groove/circlip.

Bottom line: It is probably "possible" for any Airhead built from near the end of 1983 (possibly from 1 September) as a 1984 model, to the end of Airhead production, to not have the circlip.

#1: This is the much more commonly accepted viewpoint & one I personally agree with:

The front gear teeth on the output shaft is manufactured on an angle, that is, the gear is helical cut. Its mate obviously must also have that cut and must have the same angle. Picture in your mind such a pair of helical meshing gears. If power is fed to one, then the other has force such as would try to move that gear along the axis of the shaft, not just rotated. This direction of axial force reverses, depending on powering from the engine, or engine braking. In the 5 speed transmission, even in neutral, the forward gear (5th) gear on the output shaft is being pushed forward any time the clutch is engaged, even in neutral, except in the coasting condition. A boss on the front of that gear pushes against the rear face of the inside race of the front output shaft bearing. That rear face of the inside race of the front output shaft bearing is the thrust surface for 5th gear. Simplified: 5th gear pushes against the front bearing. Another way to look at this, is that forces try to move the helical 5th gear forward and move the shaft backwards, the gear moving on the shaft. Because of this, the front bearing is always damaged, and sometimes the rear bearing, and even the rear cover plate! ....all happening when there is no circlip to prevent (one hopes) movement.

There is a tiny amount of end to end float in the shafts fitment in the transmission case (a few thousandths of an inch), established during the shimming process, which ensures that the bearings are not subjected to end-preloading. Ball bearings, used in this transmission at that point, do NOT like preloading, that would make them heat up, and then fail. There ARE some very special types of ball bearings designed for end loading, used in such as the worm drive shaft on electric winches, but this is not pertinent here (those bearings are also VERY pricey).

Prior to probably late 1984, there was a hardened snap ring, a CIRCLIP, that fit in a machined groove on the output shaft, it was just forward of the gear, & prevented the bearing from moving forward from that mentioned angled (helical) cut gear pressure. That kept the pressure from eliminating any decrease in the shimmed float. There is also a tiny spacer clip, almost a wire clip in size, alongside one end of the bearing, more on that later.

When the circlip is not installed, axial thrust from 5th gear still tries...& may well actually cause, the gear to move/push the inner race of the output bearing ...along the shaft towards the front of the transmission, as the shaft, in essence, moves rearward & the gear moves forward on it. If the bearing race moves far enough, it will eliminate any end float. This places an axial load on the bearing, that will cause it to eventually overheat & fail.

SO: the large front bearing overheats, begins to self-destruct (the cage which keeps the balls in place starts coming apart & metal goes all over the place inside the gearbox). More clearance develops, the output shaft can actually wobble in the bearing. This will, of course, start tapering the metal on the shaft; that RUINS THE $$$ SHAFT. If bad enough, the output flange on the transmission (driveshaft U-joint flange) contacts the transmission lip area where the boot is, & the output rear bearing distorts; &, with metal bits already getting into things, all sorts of mechanical mayhem happens, & rather quickly. From the first sign of unusual vibration, things deteriorate rather quickly. If allowed to proceed, gears, bearings, shift fork, & even the rear case of the transmission, are ruined.

#2: This is a far less-accepted viewpoint. I am not sure anyone still thinks this way:

This point of view is quite different. I do not agree with it. This view is that while the helical cut gear does move forward under load, it presses the inner race of the bearing, & it takes that load OK because the outer ring is against the gearbox case ....and thus the circlip is of no matter. Thus if the clip IS there, the entire shaft moves forward & the bearing always takes the axial load, & no force moves the inner race relative to the shaft. This point of view is thus that the smaller bearing should fail first if preload was a problem ....and ....there are NO circlips on any of the other shafts ....and, further, the purpose of the circlip was to assist with disassembly! During the heating of the transmission, the case should release all bearings, but a circlip-less large bearing dould remain in the case when the shafts are removed, & it is a bit of work to remove the bearing ....that one, as it is larger, sticks in the case recess ....so the clip was used. The folks who believed in this theory agreed that the clip removal coincided with the increased bearing failures ....but say that the increased failures are NOT caused by the clip removal; rather, it was coincidental with the Paralever introduction. They say that the GS Paralever introduction, with its extra travel, puts forward thrust into the gearbox, & even an angular thrust due to the changed design (dual travel angles of the Paralever), & that said angular thrust is taken up by that large 6403 bearing ....& 'proof' is that no extra large rear bearing was installed by the manufacturer. Thus, these folks believed external forces are the cause for the gearbox failures; they tend to blame too high spring preloads & poor lubrication on the splines. They feel that BMW put the circlip method back into production as it was cheap to do, & 'showed' that BMW 'did something'.

Snowbum's rebuttal: The above #2 viewpoint is faulty. Many circlip-less gearboxes on non-Paralever have certainly failed in this area ....negating the above arguments. I know of no failures of any gearboxes in the fashion mentioned in this article that were not fixed permanently by modifying the shaft (if no groove) & installing the circlip (with new bearings, etc. ...as required). I just can't buy their argument; especially when considering the thrust given by helical gears. I could write a fair more here about each technical aspect, but my reply is good enough.

Note: It has been reported to me that the stock Paralever driveshaft has exactly the same pivoting length as the swing-arm, assuming the rubber damper is OK, and as long as that is intact, there are no axial forces on the output shaft. Another reason for negating some of argument #2.

There have been several versions of the 6403 bearing sold/installed by BMW. Initially, without a very good look, all seem to appear similar to any other 6403-C3 bearing; but, the front face of the latest/greatest inner race (forward edge of the inner race, the side of the bearing which has writing on it) is cut with a 90° angle (much smaller taper to it than the rear face of the inner race) between the face & the inner hole where the bearing slides over the output shaft instead of the 6403-C3 bearing which has a tapered angle. The forward taper is almost absent. Perhaps this was done to minimize the possibility of bearing creep as the bearing is pushed against the retaining circlip by 5th gear. This modification may well have never been needed. The regular bearing worked fine, never a problem with bearing creep leading to bearing axial overloading ....until BMW started leaving out the bearing retaining clip. This new bearing may be the accepted choice ...but: the more commonly accepted view is that the elimination of the cheap clip & associated groove caused the problems ...and ...I have received word that if one now orders the 'special bearing', you might get a STANDARD 6403-C3, without the modified inner race face. The 'special bearing' was used only for awhile; then BMW went back to the regular old bearing? Not enough confirmation yet.

This is confusing, so the part needs inspection. However, the 6403-C3 bearing under part number 23-12-1-338-795 may be received by you with this ID on the bearing: NTN-TM. It will have a sharp edge on the circlip side, so the tiny ring used with it is not needed.

Modifying the shaft, installing the clip, new bearings, seals, re-shimming, etc., will be favorably priced, compared to just a new shaft from BMW. Those doing their own overhauls can have a good machinist cut the groove to accept the snap ring. Re-shimming is, of course, necessary with new bearings, etc.

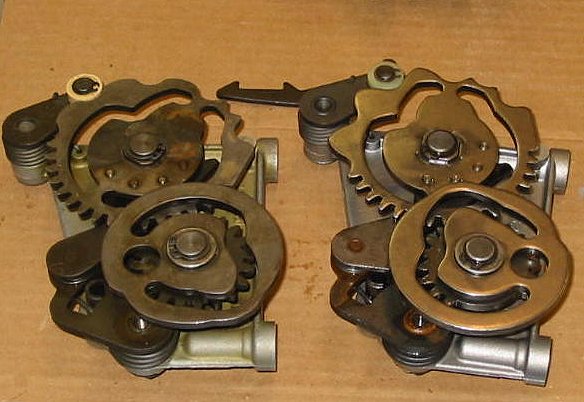

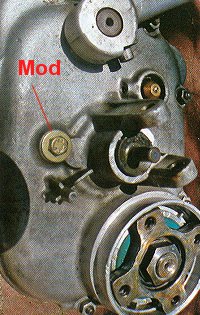

This is the 5 speed transmission gearset. Note the red line pointing to a circlip (snap ring). See links later in this article for a view of the actual circlip problem area. Notice the gear behind the bearing that the red line points to, and its mate on the center unit. Those are HELICAL gears.

Below is the 'improved' bearing, same part number, note the TM on the bearing.

MORE on the 6403 bearing! (READ CAREFULLY, and compare with above information!).

The following was copied from the Airheads LIST on 06/21/2017. The reason I am placing it here is for 2 reasons:

(1) It fully explains, together with the above information, what you need to know about the versions of this bearing.

(2) So you will have a good idea of why most owners send their transmissions out for repair to qualified well-experienced specialists with Airhead transmissions. In this case, the Specialist is Tom Cutter who does business as the Rubber Chicken Racing Garage, located at 1360 Colony Way, Yardley, PA, 19067. [email protected] (215) 321-7944.

I have edited this slightly for ease of reading, but have not edited out mistakes on part numbers.

Brook Reams asked: This bearing (part# 23 12 1 233 808) has a rubber cover over the race on the side that fits into the hole in the rear cover......

Why is this the only bearing with a cover? The new one I bought does not spin as freely as the other bearings that don't have the cover. I assume the cover adds some resistance when the bearing rotates. Is this normal?

Tom answered:

"That is a 6304 C3 2RS2 sealed bearing, with one side seal removed. BMW did that to create an oil reservoir between the bearing and cover, where particles of swarf could accumulate, and remain trapped. This also directed as much oil as possible down the center of the intermediate shaft, improving the lubrication of the free-wheeling gears on that shaft, which are turning, relative to the shaft, all the time when you are in top gear. The bearing itself gets enough oil from the shaft churning in the oil (it is partially submerged in the oil when the level is correct).

"Be aware that the BMW parts fiches have for several years listed the location and quantity of that bearing incorrectly. The half-sealed bearing goes on the rear of the intermediate shaft only. The open -495 bearing (also a 6304 C3) goes on the front (closest to the helical gear) end of the intermediate shaft as well as on the rear of the input shaft. The rear of the output shaft also gets a -495 (also a 6304 C3) bearing on the non-paralever models, The paralever models get a fully-sealed (also a 6304 C3) bearing at the rear end of the output shaft, part number 23 12 1 338 466.

Tom further said:

"Confused yet? Build a couple thousand BMW gearboxes and you will appreciate that there are hundreds of little details to know about the internals, changes, what works with what, etc. This will be my last public post about internal transmission stuff, because it is not a task that has a forgiving learning curve. People get hurt and killed when transmissions fail on motorcycles. I don't want to be the one who made people feel that a few tools and some Internet learnin' will do it."

MORE DISCUSSION:

Here is a Snowbum edited query & reply, from the Airheads LIST in November 2004, that will explain about something you might otherwise overlook if you are overhauling a transmission, etc:

The transmission was from a 1983 or 1984 R100RS. The owner decided to do an overhaul. It had been done previously, probably by him; the mileage was now around 200,000 km. He noticed a small "rumble" or notchiness when revolving the output flange, the driveshaft shaft disconnected. No sound, no notchiness when tested from the wheel with the driveshaft connected. A transmission oil change (done every 6 months!) showed normal metal powder on the drain plug magnet.

Transmission was removed & he slightly released the gearbox cover screws (1-2 turns) & the notchy feeling disappeared totally. Sounds like a preload problem?? The owner then measured the clearance between the output shaft snap ring & the big bearing (6403) inner race; the inner race pushed as far as it goes down the shaft. A 0.25 mm feeler gauge was a bit tight but a 0.20 mm loose. So, he concluded that there must be more than 0.20 mm "undefined" clearance in the shaft & it seemed to him that there is no reasonable way to shim the shaft within 0.1 mm as required especially if the bearing may drift along the shaft. The owner then felt that he would have to shim the snap ring & the bearing inner race to zero clearance.

The owner continued....(Snowbum editing here): "My actual question is about the "bearing drifting along the shaft due to missing snap ring "theory". If the front bearing inner race moves along the shaft (despite press fit) ...what ...is holding the shaft in place ...that the drift can take place? If it is the smaller bearing then the snap ring push will really prevent big bearing drift but this may cause a situation where the shaft drifts in the smaller bearing, not the big one. Again, a preload will result. He also wanted to know what happens to the bearing outer races in operating temperatures? Do they float ie. are they free to move away from their assembled positions? The operating temperature is not very far from the assembly temperature where the bearings practically can be dropped in their places.

Tom Cutter replied (slightly edited here by Snowbum):

There are several forces at work that can dislodge the bearing inner race from the shaft. One is the weight & forces of the driveshaft as it undergoes normal rotation, the forces placed upon the output shaft are cyclical, both rotationally & axially. The bearing is designed to be captivated by the clip to preclude ANY axial movement of the bearing race upon the shaft. Unfortunately, the bearing now sold for the output shaft is dimensionally slightly different from the one designed for in the original plan. That bearing had a square corner on the rear face of the inner race, so that it would press evenly upon the circlip. BMW only offered that bearing for a relatively short period, then they substituted a standard 6403 C3 bearing in its place in the parts system. The standard 6403 bearing has a very generous radius on the inner bore, which makes the race bear on the very outer edge of the circlip. In some cases the clip becomes dislodged into the adjacent void. The problem is exactly as you have mentioned, & is the cause of the premature failure of so many gearboxes. The cure is to shim the inner race so that there is no possibility that the bearing can be displaced. This can be done with flat shims, although BMW do not offer such, or by simply fitting the round wire expansion ring that BMW used for the purpose.

This round wire expansion ring sits down in the radius of the bearing bore, & effectively fills the void so that there is metal-to-metal contact from bearing to circlip (snap ring). The circlip is: 07-11-9-934-100 (size 17 x 1). This is the same circlip used on the shift shackle in the transmission, in case you get curious about it.

The round wire expansion ring is 23-21-1-235-006. BMW uses the term Expansion Ring for the wire spacer at the bearing under discussion, & the word circlip or snap ring means the part that goes into the shaft groove.

The output shaft 0.040" (1.01 mm) groove is 0.5 mm deep, located at 17.00 mm from the step on the forward end of the shaft where the 6403 ball bearing sits. Machining should be by 1.00 mm carbide tool. Be sure to check your shaft, & these numbers, don't trust me here. The groove must be very precisely located & done so that the round wire expansion ring, mentioned above, can be installed. The inner race of the bearing we have been discussing must be installed so it presses (well, touches) on the circlip. It should not be installed towards the rear (maximum space between inner race & circlip). My feeling is that if things are done precisely, then the expansion ring must be installed. However ....I have mixed feelings on that.

More on the machining, and presented differently: Oak drew a sketch with his usual very specific and accurate dimension numbers on it for the machining; from the shaft face that the pressed-on bearing can be fitted against, the circlip groove begins at 0.6693" to 0.6713". The shaft bearing fitment area is ~0.670" diameter, for the pressed-fit bearing and the cut begins at 0.6693 to 0.6713". The circlip groove begins at the number noted, and proceeds to the shaft end, with a groove cut to 0.0394" to 0.0400" in width (Oak said the maximum was 0.041"). The groove must be cut square without radius in the cut. The depth of the cut is 0.020".

Another way of saying it all (Oak posted the information in several formats over the years) was that the clip itself (07-11-9-934-100, and use only BMW's clip) was measured numerous times, and the ID measured ~15.73 mm when relaxed. If you absolutely insist on using an aftermarket clip, use one that is specified in mm (metric). The factory groove depths on the shaft varies a bit, from 15.98 mm to 16.18 mm. The conclusion was that the nominal groove diameter was 16.00 mm (16.00 to 16.02 mm OD). The bearings measure exactly 17.00 mm thick. The groove must have the edge towards the shoulder at 17.00 mm...plus perhaps up to two thousandths of an inch. The bearing needs to be snugged-up against the circlip, so the bearing cannot move.

I, unfortunately, never took photos nor drew a sketch besides the one that was on my lathe, when doing the circlip machining job. However, here is a link to an article with photos. I agree with the article, for the most part, with some hesitancy about BMW not using the round wire expansion ring at times. The article will show you what the shaft looks like, the groove being cut, etc.

http://www.gunsmoke.com/motorcycling/r100gs/tranny_circlip/index.html

Here is another article with photos. Be sure to look at this one: http://www.largiader.com/articles/circlip/

http://www.largiader.com/ is Anton's HomePage. Anton has two articles to look at, not overly clearly shown as two different links, at least not in my browser. Look on the left side, and find 'Transmission, clutch, final drive'. Put your mouse pointer over "transmission" in "Airhead transmissions and circlip problem". The word 'transmission' will be seen to be a link to his article. Click on the word. When finished looking at that article, go back to Anton's HomePage and this time put the mouse pointer over "circlip problem" and click for the other article.The throwout bearing area problem (and, pushrods, etc):

This is being put into this transmission article in case someone thinks that the transmission itself has a problem. It is expanded upon here: https://bmwmotorcycletech.info/clutch.htm

Typically, the problem shows up as clutch slippage, when the transmission gets fully warmed from riding. There have also been instances of stiff clutch, or frozen or nearly so clutch operation (not same as clutch disc sticking to flywheel in humid climates ...for that, see clutch article, above link).

Some tolerances on some transmissions throwout area bore sizes, & throwout pistons, were not held tightly enough, for the normal operating temperature range. Generally this is thought of as from 1981, when BMW changed the clutch design radically. If the piston fits into the bore a bit too tightly ...it may still operate smooth enough, but under some circumstances (temperature, as in hot!, rarely cold) may stick. Measure the piston, & if it is over about 1.13" (28.7 mm), you may want to reduce the outside diameter a bit. I have seen these as large as about 1.142" that still worked OK. I can't give a hard & fast rule here, but if yours is up to 1.141 or so, I would certainly see how it fits, & if a bit too much friction, I would recommend sanding the OD a bit. The pressure on them in operation is rather square, so if any doubt, ....if careful... you can chuck the rather short shaft tip end in a drill press and use some rather fine sandpaper for this. Inspect the bearing, & if it looks bad, replace it. Grease it with a good light non-synthetic grease (not moly). The reason to use light grease is that it takes time & miles for the transmission oil to reach this throw-out bearing. Oil the outside of the piston as you assemble this area. Clean & lubricate the arm & associated parts. BMW has a replacement piston 23-13-1-464-167 which is pricey as it includes the bearing & is a new design, that supposedly eliminates the clearance problem of the old style piston, but you do not need to purchase it, unless you cannot find a new old-style bearing (if your bearing is no good); or, you don't wish to sand your old piston, if required. Early versions of the updated -167 part may stick as the transmission heats up.