Changing the range of a torque wrench. Angular use.

Adjustment correction when using torque-wrench extensions.

© Copyright 2020, R. Fleischer

https://bmwmotorcycletech.info/IncTorqWr.htm

71C

This article explains how to use an 'extension' for the purpose of convenience (perhaps a hex or 12 point socket or an allen wrench or other tool won't fit at the end of a torque wrench where you need it); or, perhaps you want to increase the range of a torque wrench.

This article explains how to use an extension for such as the Airheads U-joint flange bolts, where you simply cannot get a torque wrench without an extension to fit properly, due to the limited room between the bolt and the U-joint body.

Another usage might be that if you only have a 75 ftlb maximum indication torque wrench and need to tighten the wheel bolts on your Paralever bike to 105 ftlbs, ....you can do it with an extension, and this article explains it.

There are only a few places on an BMW Airhead motorcycle that require torque settings over 72 foot-pounds. Because of that, many folks have no or little use for a torque wrench that has quite high settings. 75 ftlbs is a common torque wrench size. Torque wrenches are notoriously inaccurate at low settings; and I strongly suggest you do not use a 75 or 100 ftlbs torque wrench at a quite low setting, say below 10 ftlbs. Common places needing over 72 foot-pounds are the transmission output flange center nut; the ring nut & input nut on the rear drive, & the exhaust finned nuts (few use a torque wrench there, however). The swing arm locking nuts can be 72 to 75 ftlbs, not critical, so your 75 ftlb wrench will be fine there.

DO NOT use a high maximum range torque wrench for pan bolts, etc....use an inch-pound wrench. If your wrench is a metric-reading type, the same advice applies. Generally speaking that advice from me might be something like this:

Do not use a torque wrench at settings below 10% of the maximum setting....and maybe best to restrict to a bit more, perhaps 15%.

The finned exhaust nuts should be done by feel (IMO); and, I do not torque them as tight as the factory says. Cheap beam wrenches are adequate for most higher torque areas. Never use a cheap beam wrench for the cylinder stud nuts or other critical places. Quality beam wrenches and quality tubular clicker wrenches are what should always be used for more critical fasteners. If you do your own work, I suggest you have two different torque wrenches, one could be a maximum 75 ftlbs; the other should be for inch pounds, perhaps a maximum setting of 200 inch pounds. You want accuracy, so I'd not use the 75 maximum wrench at less than about 10 ftlbs, approximately. There are places on your Airhead motorcycle that are only to be tightened to 4 ftlbs, and that figure is usually critical, so you'd use an inch-pound wrench for that (set at 48 inch-pounds).

The 75 maximum footpound wrench can be used with an extension, and gain the increased torque, up to maybe even 150+ ftlbs required in a few areas. It is possible to increase the torque from a tubular clicker type wrench or a beam wrench. Actually, you can also decrease it if you wanted to.

Extending the length of any torque wrench, if used straight out, will multiply the torque shown on the torque wrench by a factor. You can set the extension at 90° and avoid any mathematical corrections as there is no change in applied torque. But, with straight-out there is a change in applied torque, and it can be substantial. If the extension piece is used straight-out, then you must compensate for the added leverage, by setting the torque wrench to a LOWER value than the specification. You must calculate the new torque setting. Thus, you can increase the maximum torque your wrench could apply, to a higher value, depending on the amount of extension used. Under no circumstances should you ever use an extension at anything but either straight-out, or, 90°, as the calculations are much more complicated.

Perhaps you have just one torque wrench, say one that reads to 75 or 100 foot-pounds maximum, and you desire to increase its maximum. That is easy to do with an extension. In order to increase the output of a torque wrench beyond its maximum setting, you must increase the leverage. This is done by extending the working end of the torque wrench, never by extending the handle in any way. In most instances the extension is used straight out, that is, parallel, in-line, with the wrench.

A calculation you might need is how much the torque is INcreased by use of the extension. TYPICALLY, however, you will just want to know how to set the torque wrench for a specific actually applied torque value.

In the instance of such as the Airhead U-joint bolts, you are likely to not be interested in extending the torque wrench beyond its maximum setting (perhaps your torquewrench is rated at 75 ftlbs); rather, you are interested in calculating what setting to use on the torque wrench, for a specified actual torque on the bolt. This is because the torque wrench already has the required range of torque settings, but you have to use an adapter to fit the bolt area, because a socket will not fit the area.

Nearly the very same process and calculations are used for all of these ideas.

The torque wrench designer assumes that the point of pressure applied by your hand is centered under your hand, at the middle of the torque wrench handle. In some instances the owners manual tells you there is a mark of some sort on the handle, used for measuring and calculation purposes, if you need to extend the torque wrench length. Torque wrench designs vary some, but the assumption remains for the handle, which is often a pivot point, whether it an actual pivot, or effective pivot point;....or not.

Consult your torque wrench owner's booklet to be sure how to do the following things for your wrench. The information in this article is usually applicable to all torque wrenches, but be sure, for yours!

This article uses inches measurements. To avoid confusion, measuring your torque wrench distances and any extension piece .... in the metric system .... is not shown. For Nm of torque values, simply take the ftlbs value and apply a standard conversion, or start with Nm, and apply a standard conversion. The conversions are:

Nm x 0.738 = foot-pounds.

Foot-pounds x 1.356 = Nm.

Many torque wrenches are now directly marked in both metric and American numbers. If you need to convert for an extension, the same principles apply, mathematically.

I will assume here that you will be doing calculations from inch measurements. If your torque wrench is metric, you can still measure and calculate in inch measurements ...or, really, any type, even metric, just use the same formulas.

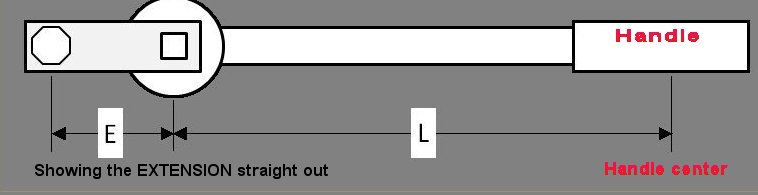

1. Measure the distance in inch measurement from the middle of the handle (handle pivot point if there is a pivot) to the center of the 1/4" or 3/8" or 1/2" square male drive. Write down the measurement, call that measurement "L".

2. Measure the length of the extension. That means the distance of the extension, from the center of the square drive to the center of the output. The extension output could be a square drive or could be a hex, such as the box end of a box end wrench, or anything else. As in the previous measurement, do it in inch measurement. Write that down. Call that measurement "E".

3. With the added extension extended straight-out as in the sketch, whatever reading you set on the torque wrench must be set lower than the actual applied torque that you want. This means that in setting the wrench for a specific torque you want to apply to a bolt or nut, the torque wrench must be set to LESS than the value the books or literature ask for. The straight-out extension is a multiplying factor, because it gives more leverage.

4. Most commonly you will want to know what setting to use on a torque wrench to get some specific torque when using an extension.

The torque you wish to apply is found by dividing L into the sum of L + E and then using the result as a correction factor.

L + E

L

Example: You want to torque the Airhead U-joint 10 mm bolts. The value of torque you decided you want is 26 ftlbs. You measure your torque wrench from the center of the handle to the center of the 3/8" square drive & find it to be 12.75 inches, that is "L". You are using an adapter/extension that is being used straight out from the torque wrench, just as in the example sketch. The center-to-center of that extension is 1.5 inches. "E" is then 1.5".

L + E is 14.25. Dividing that by L gives you 1.118, rounded. 1.118 is the correction factor.

You want 26 foot-pounds to be applied to the bolt, so, divide 26 by the 1.118 correction factor. The answer is 23 foot-pounds to be set on the wrench.

If you use the torque wrench with E (the extension adaptor) at 90° to the torque wrench, you do not need calculations. However, that usage may be physically awkward.

Rev:

07/16/2006: Slightly revised for clarity.

06/13/2011: Because of three math-challenged folks who have contacted me; I have revised this article extensively.

10/06/2012: Add QR code; add language button; update Google Ad-Sense code; simplify article once more, clarify a few details.

10/19/2012: Revise some for clarity. Remove one multiplying formula, condense and clarify methods, add sketch.

2013: language button removed due to javascript problems.

08/16/2015: Clarify a few details, and make the example one for a very common TW and common aftermarket adapter.

03/05/2016: Update meta-codes and layout.

07/31/2016: Update metacodes, scripts, H.L., add conversion factors, clarifications.

01/31/2018: Reduce redundancies, fonts, colors, improve layout, clean-up. Add 10 pxl margins.

04/30/2020: Slight improvement in explanations, reduction in colors too.

© Copyright 2020, R. Fleischer

Return to Technical Articles LIST Page

Last check/edit: Monday, December 07, 2020