SUGGESTED .... Read 15-A and 15-B, first:

15-A: https://bmwmotorcycletech.info/altcapability.htm

15-B: https://bmwmotorcycletech.info/trbleshootALT.htm

INTRODUCTION:

This article includes information on keeping the motorcycle battery charged, and wattage output, etc.... that is far beyond what advertisements for various alternators provide. Charging a battery in a vehicle like your Airhead is not as simple as you may think; nor, is interpreting the alternator ratings, typically simply shown as wattage. This article presents a huge amount of information; and, also presents information that helps you select an aftermarket alternator. I suggest you read through this article completely to get an over-view; then refer back to the areas you are interested in. If confused, please inquire on Snowbum's favorite forum, the Airheads E-mailing List, hosted by Micapeak.com. Input will help others, rather than my answering individual inquiries, which I discourage.

There is nothing wrong with the design of the stock Bosch alternators as factory installed in the Airheads. But, they age, they are sometimes abused, & they can fail, although not seen in excessive numbers. They are often never maintained until there is a failure. They are limited in wattage output, which may be of concern if you have lots of accessories ...such as lots of heated clothing, heated grips, extra headlights, etc. I am not for or against aftermarket alternators. I am reporting only facts and testing information, with conclusions. You may well do fine with the stock system. But, if you have special needs, such as big city stop and go commuting; or need more watts ...perhaps you are approaching the stock alternator limits (which decreases reliability) ...or, just need more watts ...there is plenty of food for thought in this article.

The /5 Airheads had a 180 watt Bosch alternator with the stator being 105 mm where it fit into the engine case. It can be upgraded very easily by using an early /6 stator (must be 105 mm stator), and any pre-1985 (approx.) rotor, and any /6 and later diode board.

Reliability can be improved for any alternator, stock or aftermarket, and this includes a stock /5 model, or any other stock Airhead alternator ...by using a later, better ventilated, front metal engine cover. If the motorcycle is an RS or RT, also upgrade the front painted section to the later one having louvers. Refer to: https://bmwmotorcycletech.info/altcapability.htm

DISCUSSION:

Measuring or specifying generator (alternator) output in watts is not as simple as it may seem. The simple part is that watts is equal to voltage multiplied by amperes, so the output of the alternator can be measured in amperes and volts, multiplying those together would give you watts. BUT, there are MANY complications.

The output of the alternator system should be specified and measured at a practical & usable voltage. It is wrong to use alternator sales brochures in which voltage, perhaps not even stated, is not high enough to keep the battery charged; or, at least close to fully charged. It is possible for the system output voltage to sag from a large load (big headlamp, driving lights, heated clothing, poor battery, etc). If the output voltage was too low to keep the battery fully charged; yet the current availability was high, it is possible for false wattage advertising. What is important is the real output with a "reasonable & usable" charging voltage at the battery, that keeps the battery charged enough to have good battery life and be able to restart the bike over and over again. You want reasonable fast recharging, after such as starting, or being at a traffic signal for awhile. The "reasonable & usable" battery voltage can be argued about. If a battery is fully charged at a resting voltage of 12.7, and the system is so heavily loaded that only 12.4 volts is at the battery during vehicle operation, that is barely acceptable, because if the battery is over ~ 11, the bike will run OK ....but a battery at 12.4, or lower, is not fully charged, and hence is deteriorating. The owner really needs to know if the alternator will produce a full charge during extended cruising; as well as knowing what the performance will be in stop and go traffic. The charging system should be capable of handling all the electrical items likely to be in use at the same time for reasonable periods of time.

Other considerations:

If the voltage is too high, the battery could deteriorate from too much voltage being applied, which also means too much current, which means wattage (heat) being produced by all that electricity flowing into the battery. The battery could overheat & warp; or use water too fast, or if a sealed type it might have enough internal pressure to open the safety valve (VRLA types and other sealed batteries). Excessive voltage output has NOT been any problem in any of the systems tested, if they are operating properly.

You want the battery to recharge quickly after starting the bike; or, especially from long periods of waiting at stop lights and then riding off. If the battery terminal voltage falls to 12.6 (or below) while on the highway, that is not enough voltage to truly maintain the battery at a full charge. In fact, if the battery terminal is below that voltage, the battery is beginning to be drained. Another consideration is if the alternator capability is very high, excessive recharging current could damage the battery.

You need a considerably higher charging voltage than 12.7, to enable the battery, due to inefficiencies in the battery chemistry, to reach full charge in a reasonable amount of time. This can become critical when doing stop and go riding in city traffic.

When you stop where you are going, be it work or home or other, you want the battery to be fully charged ...or nearly (or, reasonable ...or, take your pick of words here). If you ride to work, in stop and go city traffic, and the battery does not get over perhaps 12.3 to 12.6 at the time you park the bike for the day ....then the battery is not fully charged, and is deteriorating that day. It may well start the bike. It may well fully charge on the way home if traffic is lighter, but some damage was done.

If your battery is old or otherwise poor, and here I mean the internal resistance has increased a fair amount, then the battery might still start your bike, and might still show a full charge as far as voltage is concerned during charging or resting after charging ....but the battery terminal voltage will sag, often quite a bit under load ....and measurements for alternator output/performance will be tricky to accomplish accurately. The initial testing on the Omega 450 and 600 were done on the same motorcycle, with the same poor battery, which happened to be the popular Odyssey type. Later, a brand-new Panasonic battery was used, and the tested alternator performance that battery is also noted in this article.

There are three basic reasons for an aftermarket system; (1) you need more usable watts; & (2) you believe a new system will give more reliability; & (3) you'd like some additional or more usable watts to be available at idle or low rpm; or, not much above it, which is helpful for stop and go riding in big city traffic. Idle rpm output, or slightly above idle rpm output, should be sufficient for normal use, as this is one of the complaints about the stock system, in stop and go commuting use.

The idle rpm of Airhead motorcycles should not be set below 900 rpm, no matter what you read elsewhere's, and no matter what alternator, stock or otherwise. 900 is OK for early heavy flywheel models, but I recommend a typical target of 1000 to 1050 rpm for idle rpm, after a full engine warm-up (5 miles or 10 minutes perhaps minimum) at the normal altitude and temperature you ride in, for all models. These figures were selected by me for a variety of factors, including carburetor performance & synchronization; and especially for good timing chain compartment lubrication.

There is an effect I will call hysteresis. Due to certain factors, such as the minimal but notable magnetic memory of the rotor, together with the rotor current turn-on characteristics of the voltage regulator (in conjunction with the GEN lamp current-passing ability on non-permanent magnet type alternators), you will find that to initiate usable electricity from the alternator, you need a certain RPM. Once that RPM, or higher, is obtained, you will get some sort of output from the alternator as you lower RPM a bit below what was originally needed. This is not a necessarily totally and always repeatable situation, depending on how low the RPM might reach now and then during the ride....but the effect is notable. The hysteresis of the 600 watt alternator from Emerald Island (Omega) was fairly pronounced. This characteristic allowed that alternator to operate rather decently in the low RPM area usually seen only with permanent magnet alternators.

The charging characteristics of batteries of different types varies. For most types of lead-acid batteries, if one applies a voltage of about 12.8 constantly to a fairly discharged battery, .....eventually, ...and this could take a long time,... the battery would reach approximately full charge and then require very little current, from the charger or system, to maintain that stabilized voltage. Unfortunately, that voltage is much too low for practical on-road recharging. The battery needs a higher applied voltage for reasonably quick re-charging. Some battery types, notably the AGM/VRLA types, are quicker to convert chemically to a full charge, but still need considerably more than 12.8 volts of alternator output. Battery charging is a CHEMICAL change thing.

Batteries vary rather widely as to the current needed from the alternator to maintain a specific voltage. A typical 'flooded' type of battery of motorcycle size (I will use the larger motorcycle size, about 28AH, as illustration), will need about 1 to 3 amperes to maintain about 14.1 volts at the battery terminals. Gel and AGM type batteries will be somewhat different. The 1 to 3 amperes has nothing to do with what the rest of the motorcycle will require for ignition, lights, etc. One to three amperes at 14.1 volts means that just maintaining the battery after it reaches full charge will require 14 to 42 watts constantly from the alternator! If the battery has deteriorated considerably, and depending on the type of aging, the requirement can be a lot more.

A battery requires slightly higher voltage to re-charge properly at low temperatures. As temperature drops, a VR that is well-designed should increase its voltage setting slightly, and vice-versa. A tenth or three tenths of a volt is typical, with maybe another tenth if the temperature is freezing or somewhat below.

BMW's original VR settings for the stock bikes was actually ~13.8 volts. I have always felt that BMW was wrong in selecting 13.8 volts but I understand why; which has to do with keeping water use low from the flooded batteries of the day, and some minor other things. The Authorities (Police) VR is set to approximately 14.4 'at room temperature'; that works out to be the best setting for most-all types of lead-acid batteries, in so far as keeping a full charge. As I have noted, most voltage regulators have a voltage versus temperature effect purposely built-in. This is because the voltage needed to maintain any given charge percentage on a lead-acid battery will vary with temperature, and, the chemical conversion works faster with a slightly higher charging supply voltage when the battery is cold. The voltage regulator ideally is mounted in the same airflow as the battery; it's pretty close to that, temperature-wise, in the Airheads. Generally, there is only a few tenths of a volt compensation, from perhaps 120°F down to perhaps 20°F ...the typical range of temperatures seen by the battery and VR. Note that in heavy slow-moving traffic, in quite hot weather, the temperatures reached can be quite high. Motorcyclists may ride where battery temperature will exceed 140°F (typically from engine heat blown over the battery). Some do ride when the weather is well below freezing.

As the battery temperature falls towards freezing and below, the battery has a much more difficult time (after all, it is a chemical reaction device) producing the current (call it that or power) needed to start the engine. The engine has higher friction due to cold/thick oil ...and decreased clearances from metal shrinkage. Thus the starter motor is going to need ...and use ...much more battery current than if the temperature of everything was much warmer. When cold, the chemical conversion in the battery to produce electricity gets more sluggish, and this is not only in battery delivery of electricity, but in re-charging, hence the higher charging voltage. So, in cold weather, everything is much harder on the electrical system. For the nerdy types here, the battery charging efficiency goes up and down by AT LEAST a factor of 2, for EVERY 10°C of change of battery internal's temperature.

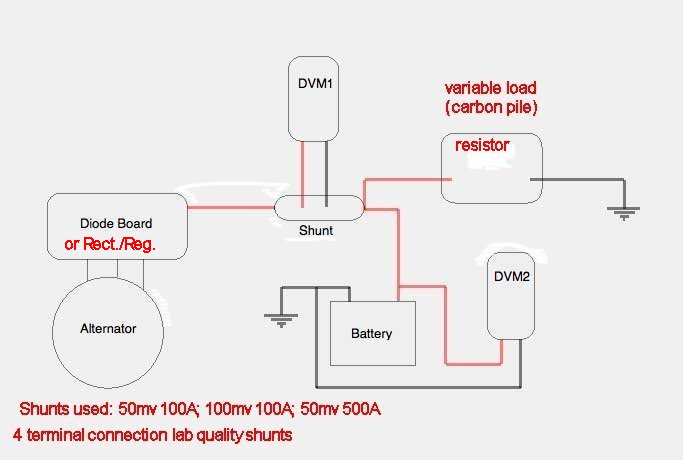

Schematic diagram of the circuit that I used for testing all alternators; with few differences. Note that wires were of very large gauge, and connections also large, to avoid errors.

The STOCK Bosch Alternators:

BMW has used several versions of the 'stock' Bosch alternator in its various Airhead motorcycles. The lowest output version was rated at 180 watts and used only on the /5 models. The highest output version was rated at 280 watts, used in the /6 and many later motorcycles well into the eighties. The R90S alternator was rated at 238 watts due to increased clearance between rotor and stator, as crankshaft whipping was anticipated at the higher maximum rpm that was often used on that model. The last of the Airheads also had 238 (published sometimes as 240) but began charging at SLIGHTLY lower rpm than earlier models (~same as certain specific early Authorities models). The following table shows true actual usable output of the stock 280 watt Bosch alternator, using 3.7 or 2.8 ohm later models rotors, early eighties stator; known perfect connections, wiring, battery, switch, etc. You can expect to get very close to the rated output from Bosch alternators, if your system has good solid connections, etc. I will say that differently: The stock Bosch alternator will do what the ratings say. NOT so with most/many aftermarket alternators.

Some aftermarket alternators have 'overly optimistic' output ratings. You will be able to see that in this article.

STOCK Bosch alternator, rated 280 watts:

|

RPM |

Output, amperes |

NOTES |

|

1050 |

2.5 |

Battery is discharging |

|

1550 |

10.0 |

~ Point of equilibrium with the stock drain of lights and ignition |

|

2100 |

15.0 |

~5 amperes available for charging |

|

2850 |

20.0 |

Maximum available. Battery 13.5 v & rising. 270 watts. Very slightly more wattage available as voltage rises more. |

|

|

Only 2100 RPM needed constantly, but that's lower than you should cruise at. |

watts = voltage multiplied by amperes |

Conclusion:

The stock alternator produces very close to what Bosch specified. The voltage is a decent value, & above the minimum needed by the battery to maintain a full charge, even at maximum output, with stock electrical equipment.

The tests on the original 400 watt, 450, and 600 Omega were not as extensively done as I did on the EnDuraLast. For the EnDuraLast, testing included effects of temperature, oscilloscope indications, stress gauges to see how the crankshaft might be affected, hot/cold differences, etc. What follows for the 400 watt early Omega is probably what you could actually expect of it.

Testing on the Omega 400 was with a known accurate ammeter setup with short heavy gauge leads, connected in series with the Omega diode board output. The known and tested good battery was drained somewhat to begin with (on purpose); and, a digital voltmeter was placed across the battery posts themselves. Readings were taken well before the battery was recharged, with heated grips, accessory lights, and headlight ...all turned on. Readings were repeated with lights off, & also with the battery fully charged. The "set point" of the VR appeared to be close to 13.8 volts. I consider that too low for best battery life and system performance, but it does extend intervals between adding water on flooded type batteries.

NOTE: Battery was loaded with a resistance box (carbon pile type) to obtain the 'less than fully charged' voltages. If not so loaded, the alternator would show usable output at 1550. The first chart below is a summary, & where you see two instances of the same RPM with lower/higher voltage, that was due to battery charge condition at the instant of measurement, & small deviations from expectations, due to, I think, heating, carbon pile setting, etc. That information is more useful to nerdy types like me. This effect is much more prominently shown in the test of the 450 and 600 watt alternators, further down this article, due to a higher internal resistance battery to begin with.

|

RPM |

Voltage at battery |

Output in amperes |

Watts |

| 1550 | 11.70 | 2 | 23.4 |

| 1700 | 12.5 | 5 | 62.5 |

| 1750 test 1 | 11.83 | 8 | 95.6 |

| 1750 test 2 | 12.5 | 5 | 62.5 |

| 2200 test 2 | 12.8 | 12.5 | 160 |

| 4000 test 1 | 12.64 | 28 | 354 |

| 4000 test 2 | 13.5 | 20 | 270 |

| 5000 | 13.2 | 31.5 | 415.8 |

| > 5000, no improvement |

|

|

|

|

|

|

||

|

|

|

You would need ~2400 rpm to equal the output of the stock 280 Bosch at 2100. THUS, you can rightly assume that this alternator is not any better for constant stop and go in town, unless you have a bit of distance between stops; OR, you can use higher RPM between stops! Longer distance between stops would also help, perhaps, wild guess, a half mile or more.

Note carefully the two 1750 & the two 4000 rpm tests. Note how the wattage varies with the voltage. I specifically loaded the system in order to enable these readings. What especially interests me, Mr. Nerdly, is that at 1750 rpm, a heavy load that dragged the system to 12.5 volts produced 95.6 watts, but the voltage was too low to fully charge the battery, although safe enough. Compare carefully to the two 4000 rpm tests.

You can see that the battery would be marginally charged at 4000 rpm if 28 amperes of load was used. This resulted in 354 watts. If the load was decreased, the voltage rose to 13.5 volts. That is still not enough floating voltage (IMO) ...I'd prefer to see 14 volts or even a bit more; but it IS OK. Increasing rpm beyond 5000 did not yield increased output. If using this alternator, performance will be additionally enhanced by using a voltage regulator set point of 14.1 to 14.5 volts. The voltage regulator was not the adjustable type on this tested bike. The battery was also not new. The ammeter & its leads & connections add a small series resistance; this would have the effect of moving the output higher up in rpm (although slight and only a bit more at highest outputs). This also applies to the Bosch and EnDuraLast during tests.

This alternator can produce considerably more total wattage than the stock 280 Bosch. I think that considering riding patterns in cities, using lower gears, higher rpm (for any alternator), would mean this alternator would do considerably better than the stock alternator in all normal conditions, city stop and go and cruising on trips.

It is interesting to compare figures with the stock Bosch system. The Omega output was low at low rpm, but it rapidly overcame the stock system as rpm into the cruising area was attained.

It is important for those with considerable need for more wattage, to understand that the output of this 400 Omega is ultimately higher than the EnDuraLast ....but the EnDuraLast has much higher output at truly low rpm, & is probably better for city commuters, especially if their electrical needs are modest. Things change with the later higher output Omega alternators, tested below.

The weight of the Omega is nearly identical with the stock Bosch; differences are so small as to be of no concern.

Omega 450 watt and 600 watt alternators (400 looks almost identical to the 450):

Scot Marburger has written up what and how we, together, did the testing, etc., in April, 2016. We finished the final testing June 12, 2016. You may be interested in reading his article ...and it has a lot more information about the installation, why's, how's, etc....and...more photos!

http://www.gunsmoke.com/motorcycling/r100rt/alternator/index.html

Note the much increased number of magnetic poles on the 600W Omega (Emerald Island Co.) stator, in the below photo. Also note the last version of the stock Bosch alternator stator in the second photo. There is also a considerable difference in how the windings were designed, between the 400 and 450 and Bosch (as a group) and the 600. The 600 does everything possible to have a larger rotor and stator, that will still fit into the motorcycle without machining being necessary to the motorcycle case.

Note: If your battery is poor, perhaps old or mistreated, it's internal resistance has probably increased a fair amount, and possibly a formal load test instrument would show so-so performance. The battery might still start your bike, and might still show a full charge as far as voltage is concerned (during charging) ....but the battery terminal voltage will sag, often quite a bit, and measurements for alternator output/performance will be tricky to accomplish accurately.

The testing of the Omega 450 and 600 were done on the same motorcycle, with the same poor battery, which happened to be the popular Odyssey battery. Testing was done with a commercial laboratory grade 50 Mv 500A shunt, with a quality digital meter connected to it for ampere output testing. The shunt was connected in the diode board output lead, so measurements were of actual alternator output only. A digital meter was connected across the battery terminals. A carbon-pile type adjustable load resistance was connected across the battery in such a manner that the digital meter connection at the battery was not affected by the load connections at the battery from the bike, nor, the carbon pile adjustable resistance. BOTH alternators were tested using the same diode board, same motorcycle. Dates of testing: 04/16/2016, 04/17/2016. Further testing was done 2 months later, using a brand-new, fully load-tested battery. That information is in the following charted area for the "600". For all tests, figures include repeated testing at same RPM, but differing loads and state of battery charge. Testing was done with alternator parts relatively cool, that is, the front cover was off, and the bike had not be ridden before testing. I would expect some decrease in performance in actual on-road testing, or 'garage' testing after a full warmup.

OMEGA "450" alternator:

Tests were run at a variety of conditions, on a 'weak' battery, that had moderately high internal resistance. The battery was loaded to a variety of high normal, normal, and also several voltages below 12.7 (12.7, resting, is considered fully charged), to find out what the maximum output was. To obtain the output we saw at 1550 rpm is exceptionally good.

|

RPM |

Battery Voltage |

Output Amperes |

Watts |

| 1550 | 208,194 | ||

| 1700 | 246, 263, 269 | ||

| 2100 | 306.5 | ||

| 2200 | 352.3 | ||

| 2850 | 420 | ||

| 4000 | 515 | ||

| 5000 | 13.0 | 41 | 546 |

| 5000 | 13.66 | 39 | 533 |

Omega "600" alternator:

The first series of tests were run in April, 2016, on a variety of conditions, on a fairly weak Odyssey battery, that had moderately high internal resistance. We tested both the 450 and the 600 alternator, see above for the 450 results. The battery was loaded to a variety of high normal, normal, and several voltages below 12.7 (12.7 is considered fully charged), to find out what the maximum alternator output was. To obtain the output we saw at 1700 rpm and higher is exceptionally good. Testing was additionally done on the "600" alternator at 1700 RPM with various very substantial loads (far beyond normal use even with large extra headlights, etc); with battery voltage drained/loaded to give 11.79 and 10.58, both of which are well below that needed to maintain a decent battery charge. This loading was probably not possible except for the poor battery. Testing was done for same reason at 2200 & 2850. Conclusion: Even with a bad battery or exceptionally large loads, the engine would stay running and get you home. It is difficult, even normally with a very good battery, to do these tests, as the load needed across the battery would be huge in order to reduce the battery voltage quickly. Luckily, we had a poor battery, making it easy to use a Harbor Freight two-meter battery load tester for the adjustable load ...but making it twitchy and somewhat difficult to take quick readings. That meant one person at the throttle watching the tachometer and one person with two meters and the load adjustment responsibility. Note that the method of testing will over-rate the alternator normal use output; but it is real-world for cold conditions and absolute maximum performance. The performance of the Omega alternators is very good. A second series of tests was run on the same bike a couple of months later, same alternator, same basic connections/conditions, except that the bike was equipped with an almost brand-new battery, and it had just been load-tested. The results are in the table below the next one.

Below table is for the original tests on the "600" with poor battery.

|

RPM |

Battery Voltage |

Output amperes |

WATTS |

| idle | 12.6 | 4.9 | |

| 1700 | 14.2 | 15 | 213 |

| 2200 | 11.6 | 38 | 440 |

| 2850 | 12 | 54 | 648 |

| 4000 | 12.6 | 67 | 844 |

| 5000 | 13.76 | 61 | 839 |

|

5000, max output test

|

12.35 | 73 | 901 |

Below table is for the second series of tests on the "600" (this time with a new, load-tested battery): These tests were done June 12th and June 13th, 2016. Besides an identical setup and the new Panasonic battery, various other tests were made, including a look at the alternator A.C. output at the alternator itself (pre-shunt) as well as at the battery (after shunt), using a dual-channel oscilloscope. Testing was more extensive on voltage and current and RPM. Repeated tests, engine just warmed (also when quite hot) were done, in multiple tries. Scot had set the voltage regulator some time ago, and my dynamic measurements showed that the set point for cut-back was ~14.08 volts. I believe Scot uses ~14 volts to extend lamps life. I would have preferred 14.4 at 70°F as measured at the regulator metal case. Note that a considerable amount of the much earlier discussed hysteresis was seen. This was looked-into several times. It required about 1600 RPM for output to begin, at which time the RPM could be backed off ...and output would continue to be quite usable down to about 1200 RPM ....although battery voltage sagged somewhat below that necessary to maintain a full charge. Testing was done at 1500, 1600, 1650, 1700 RPM to see what type of battery voltage could be maintained. This was done with the headlight both on and off. Tachometer was read ABP, and had not been calibrated. The battery was purposely loaded heavily in some tests to obtain a low voltage for maximum alternator output measurements. Such low voltage would, in cruising conditions, mean considerably less than full charge ...but totally usable to get to a destination, even a very considerable distance! Some tests may be difficult for you to understand. This is because the battery was heavily loaded (typically 40, 50, and 90 amperes). This especially was so for wherever you see the same RPM being used. Below table is for tests on the "600" with the new battery; note again that the VR setpoint is 14.08v, warm.

RPM

Battery Voltage

Output amperes

Watts 13.64 24 300 5000 13.83 40 553 Unfortunately, we did not do testing at idle rpm and off-idle position, for voltage and wattage, for stock electrical loads. It is my belief that the results would be good. Conclusions: The stator is beautifully machine-made, and has many more magnetic poles (it is not just a larger alternator) than the older stock Bosch alternator. I would love to see results of a re-designed rotor with additional pole pieces. The EnDuraLast Alternator, the original permanent magnet version: I did a careful installation & very complete and full testing to evaluate the performance, installation, and every sort of conclusion including practicality, of the original EnDuraLast "Permanent Magnet" alternator system. This was done during the time of pre-release, prior to sale, of the alternator by Euro Motoelectrics. The wiring installation was first done using the original instruction sheet available at that time. This included both with and without wiring and Rectifier-Regulator mounting areas modifications that I thought best changed during original testing. The original purpose of doing this installation was to do testing and recommendations for Euro Motoelectrics, to help them prepare the entire installation kit for sale to the public. Our agreement was that I was free to publish what I found, no matter what that was. I found some things I was unhappy with, most were fixed before release/sale, but not all. The motorcycle used was a 1984 R100RT. A known (and tested) perfect battery was used, and same for the condition of all the connections, wiring, etc. in the electrical system (prepared very carefully, during installation and before the tests). The system used light electrical loading & was allowed to fully charge the battery according to the system voltage regulation (14.24 in this conversion instance). Then the battery was loaded moderately for a while until a known value of battery decrease in voltage was noted. At this point the output was measured by starting the engine (which additionally slightly drained the battery), & then I used, quickly, various rpm during immediate measurements. That is a simplification of the various tests I did. My method for testing other alternators, whether aftermarket or stock, is the same, although the voltage noted above might be different, depending on if a fixed setting, or if it was adjustable ...and if so, if I adjusted it. I used a heavy duty commercial millivolt shunt and lab quality metering ....and carbon pile type loads. I tested using the motorcycle's own lamps, ignition, etc. ....and if large aftermarket headlights have been added, also added testing with them both on and off. The weight of all removed stock Bosch components: diode board, stator, rotor, housing, regulator, some wiring, etc., is 87 ounces; all the EnDuraLast items as installed will weigh almost exactly the same. For the Omega, as noted well above, weight is also about the same as the stock Bosch. Leakage current: under 1.5 MICROamperes, worst conditions. This is very good. Rotor diametrical clearance to stator: 0.006-0.008". This can vary some with the components, as well as the exact fitment of the inner timing chest to the engine casting, which is adjusted slightly during a timing chain or other similar R/R job. Rotor runout, axial: negligible. Rotor lateral runout (side to side): 0.00075" maximum. EnDuraLast Rectifier/Regulator: In most vehicles, the regulator is usually mounted in an area that allows some engine heat (comparable to battery temperature in a modest way), to influence it. In most quite modern cars the regulator is usually part of the alternator itself, often combined with (part of) the rotor carbon brushes assembly. As the alternator temperature changes, the regulating voltage increase or decreases slightly, and so designed that way on purpose, to match battery temperature characteristics. This is not necessarily so on this conversion; depending on where the regulator is mounted, and how (it generates some heat internally). From my testing results, the EnDuraLast RR unit is OK over at least a normal temperature range, and I do not consider its location to be of high importance, except that it should be kept away from areas of high heat to extend its life. This means it should not be mounted to engine metal parts. For technical reasons, that I will get somewhat into later here, I recommended that the RR unit be mounted near the battery and very solid connections be part of the normal installation. This was recommended to be so shown in the installation paperwork supplied with the kit. I ALSO recommended that they do NOT use the "bullet connectors" method that the alternator was shipped to me with ...as they are a place for poor electrical connections, and I additionally recommended certain use of short length grounding leads; appropriate wire gauge sizes, etc. I purposely wanted to do vigorous testing for the manufacturer of this conversion kit; and I so promised them. I initially mounted the RR in the left vent of the R100RT, leaving me the ability to close the vent, even when riding, to nearly eliminate any air flow. The RR was mounted to the inside of the vent structure using a thick backup metal plate, and a electrical temperature probe was affixed, which was connected to a digital temperature meter. There had and have been reports of RR unit failures when high levels of alternator output are consistently & continually used. The analysis showed the cause to LIKELY be overheating. I determined that the best and most practical mounting position on an Airhead motorcycle would be where the RR unit is exposed to relatively cooler air and not much subject to much immediate engine heat. My recommendations included mounting it in a particular alignment of its fins, to the left downtube of the frame next to & behind the battery. This has an added advantage in that the output can have short thick gauge wire connections which are, for very technical reasons, a good idea, as opposed to the alternative, which is shorter stator connections. The EnDuraLast voltage regulator (VR) is supposedly internally fixed at about 14-14.26, and hence a small amount more of the EnDuraLast output is used to keep the battery fully charged, than with the stock voltage regulator setup. This is a minor point. A good thing is the regulated voltage at the battery is high enough to keep a full floating charge on the battery during most uses. Anything over about 1500 to 1600 rpm is adequate to supply the stock motorcycle, or, with one with an added headlamp or perhaps heated clothing. That means that an RPM that is much lower than cruising RPM is going to produce plenty of available wattage. Below are charted results for the EnDuraLast in the 1984 R100RT. The tachometer notations are calibrated accurate. See information much further downwards about later tests on a different bike, a 1995 R100RT; and, a different type of installation, conforming to the latest instruction sheet. MAX Conclusions: Note that for the otherwise stock motorcycle, & no additional electrical loads, the EnDuraLast alternator will maintain a reasonable charge at about 1100 rpm. This means that keeping the battery charged during stop and go big-city-type-commuting is not a problem. This, only, is where the EnDuraLast is particularly good. Re-said, differently (and, brought up to date, as the Omega's were not, back then, available): The EnDuraLast is, in SOME conditions, better for in-city stop and go, than the stock or Omega alternators; considering all factors, including costs. The Omega's are better for high output, and for maintaining the preferred higher battery voltage at such a higher output ....a dual benefit. Best performance of the Omega units is with a bit over 14 volts set-point of the voltage regulator. NOTE that the large Omega's are likely going to be quite reliable ..particularly so if maximum output is not needed/used. The 450 and 600 Omega units, when lots of extra wattage is needed, will be much better than the EnDuralast Permanent Magnet alternator, provided that extended idle rpm performance is not an absolute requirement. What follows in this long section are nerdy points, some conclusions, further information, then an Addendum, and then some Final Conclusions: It was noted that the Regulator set point for the original early EnDuraLast that was tested, at 84°F, was 14.48-14.50 volts, which is higher than expected, and somewhat more to my liking than the early Omega. Since the set-point is slightly affected by where the regulator is mounted on the EnDuraLast; ...due to wire gauge size and length between stator and regulator ...your voltage may be a bit different if you have your regulator mounted next to the battery (which is a good place, and was my suggestion to the developers). Note that the wire gauge size in the stator itself can not be changed. My installation originally had the regulator mounted in the R100RT fairing air inlet area ...where I could control temperature by controlling the air flow, etc, for my testing. I suggested to John Rayski that his literature reflect my findings. I also suggested, as I have noted, that the bullet connectors method not be used, the RR mounted next to the battery, the installation instruction sheets be modified, etc. Some of my suggestions were taken and adopted. 1981 & later BMW airhead motorcycles; & earlier models with aftermarket electronic ignitions, can be sensitive to electrical noises in the electrical power supply. That is one reason, of several, including that the old mechanical regulators had aging problems ....that the original mechanical VR in the stock motorcycles were changed to an electronic type in 1981. That eliminated the vibrating electric contacts, with their mild arcing, from producing undesirable electrical noises that might interfere with the ignition. Additionally, some electronics, including diodes and a RR power regulating transistor or other certain types of electronics circuits, can create their own high-frequency spiking type of electrical noises, that are not good for several things, including the ignition and tachometer and perhaps radio items, intercoms, etc. Thus, tests with an dual-trace type of oscilloscope were going to be run on the system; one trace monitoring the battery,

and one trace monitoring the ignition pulses. As you have seen, the EnDuraLast did not do what its advertisements said (this was reported to the makers, and they did modify the charts, not fully, however), regarding output, performance curve, etc. Considering that the EnDuraLast system was provided to me without cost, and for me to keep; in return for my comments, technical advice, etc, ....all this from the manufacturer of the system; ...please be assured that my comments, or negativity in some areas in this article ....certainly reflects my independent thought. This may also be seen somewhat differently, as the Omega's were not available and/or untested, at that time, but the Omega's WERE available later, and additional testing and comparison was done with my own 1995 R100RT EnDuraLast installation (not done by me, but the prior owner, but I did improve the mounting and wiring and connections, etc.). Reports on that installation are later in this article. As noted, my testing results did not duplicate the specifications/information on output performance of the EnDuraLastn PM. I did try to improve the installation (one of things I promised to John Rayski). I made some minor changes, eliminating some small voltage drops... which helped some. I thought about these things at some length, and some improvements, such as eliminating the troublesome bullet connectors was done. I had an idea of what may have been part of the output problem. The stator output is via two wires, with no grounding reference. That is, the output is a form of single phase, which is much less efficient than the formal 3-phase output of the other alternator systems in this article. The EnDuralast Rectifier/Regulator unit, which is sealed from investigation, could, and probably does, have a circuit that involves a type of multiple-diode rectifier called a "Bridge Rectifier". That function can also be done with special transistors acting like controlling diodes (and, hence, act as regulators); or, by power diodes. I did not test the output of the RR unit via an oscilloscope to try to determine the type of rectification. For my own curiosity, I should have....although the end result would mean nothing for performance, as that is fixed by the inherent design. While a half-wave rectifier could be used, use of that type of circuit is illogical, as output would greatly suffer; and, the extra parts for the better bridge-type are inexpensive. This discussion of rectifier types is really quite nerdy here. What is still nerdy, but actually of some importance, is that a property of a two-wire source (here, the stator winding) to any type of rectifier, is that the impedance (nearly the same thing here as resistance) of the stator and connecting wires from that stator, can be relatively higher (than the rectifier's wire size/length in the output to the battery), with little deleterious effect. That means that the stator wires ...the EnDuraLast yellow wires ...can have more resistance in them and still get decent output; but, the red wires output, and the case ground output, will need far heavier gauge wires, and negligible voltage drop in connectors and connections. The electrical reasons are not easy to explain to someone without serious knowledge of impedance/resistance and magnetic coil characteristics. Still, even with such a modification, the output did not come very close to specifications. I was able to get a modest improvement (about 1.3 amperes, nearly 18 watts) by simply repairing just the bullet connectors of the red wires as furnished by the 'manufacturer', Euro MotoElectrics. This was reported to them, so that their kit could be upgraded/improved. Further improvement will be possible by mounting the RR unit next to the battery due to the very short output-side wires then possible, for reasons noted above. My recommendation to the makers of the EnDuraLast kit was to mount their RR assembly to the battery carrier, which would be a decent heat sink also. At the time, I had not tested my idea, but I have, since, & there is a small improvement. Additionally, later, the mounting of the RR was placed onto the frame down-tube on the left side of the battery area, which exposes it to additional cooler air ....this will likely lengthen its life, and is an acceptable mounting point, although perhaps less neat-looking than the more hidden area at the battery box. A matter of viewpoint or personal preference. ADDENDUM: Results: The various testing results reinforce my statements, condensed here, that the EnDuraLast may be an alternator you could seriously consider if you are doing stop and go city-commuting and have no need for high wattage output. IMO, it is NOT the alternator to purchase if you need considerably more wattage. There may be some additional drawbacks to the EnDuraLast alternator: Over-all conclusions, in brief: 1. The stock 238 to 280 watt Bosch systems are adequate for most Airhead riders. In fact, testing, not shown in this article, on a /5 alternator (180 watts) shows it to be adequate in many instances. If driving lights, heated grips, and other accessories are contemplated, the stock alternator on any Airhead may be marginal or negative on electricity generation, depending on what you add or change. It depends on how much additional load is being actually used, for how long, and what the average rpm is, peak rpm, and idle time. Very difficult to make a definitive statement, as riders differ in how they ride and use the engine. See other alternator articles on this website, including:

https://bmwmotorcycletech.info/altcapability.htm 2. For inner city commuters (doing a lot of short distance stop and go) with modest electrical loads, you might consider the EnDuraLast permanent magnet system. The output at just over 1000 rpm makes this a reasonably decent choice for stop and go inner-city commuters. There may be some additional drawbacks to the EnDuraLast alternator; but, consider these things: The permanent magnet rotor in the EnDuraLast alternator has fan blades at the forward end. Due to the fan proximity to the cover, etc., the fan makes a small amount of whirring noise during operation, that varies with engine RPM. This has been remarked upon now and then, but is not annoying, unless you have 'just' noticed it. The installation requires modifications to the motorcycle wiring system. This may or may not be of concern to you, during the installation.......or..........if contemplating a return to the stock wiring at some future date. The exact reasons behind some reported EnDuraLast RR failures are not known to me. There may still be restrictions on the type of battery being used. See latest installation instructions. 3. The "400" Omega is a usable alternator for touring; but, the later 450 and the latest 600 Omega alternators are more than adequate for almost any type of commuting or cruising/tours/etc., even with substantial added electrical devices. I can't recommend the "400" if you are contemplating it mostly for stop and go commuting. 4. With the 450 or, especially, the 600 watt Omega (Emerald Island), there is now no overwhelming reason to install the EnDuraLast PM alternator, even for city commuting situations. Price can be a factor, however. I want to be fair, and the permanent magnet EnDuraLast alternator has better performance at quite low RPM (compared to even the 600 watt Omega-Emerald Island) ....and there is no hysteresis effect that is possibly a problem (typically NOT). But, the EnDuraLast PM has much less maximum output. 5. I make no definitive statements here on longevity/reliability of any of the aftermarket systems. There have been failures, but nothing of serious note .....AFAIK. 6. Reliability should be improved for any alternator, stock or aftermarket, and this includes a stock /5 model, which has a 180 watt Bosch alternator; or, one upgraded to a 280 watt 105 mm Bosch, by using a later, better ventilated, front metal engine cover. All Airhead stock AND aftermarket alternators should have the better ventilated front metal engine cover. 7. Reliability is improved, if one has a RS or RT with non-louvred front fiberglass cover, by installing a louvred one, or by making big slots in the solid fiberglass cover. 8. Reliability and charging performance is improved on the stock Bosch systems by installing metal diode board mounts on models having rubber mounts. One needs to have proper grounding wires in any case, although the extensive extra spider wiring BMW installed or recommended by installed, is NOT necessary. The info is in another of my articles. Be sure to read the diode boards, etc., article.. © Copyright 2021, R. Fleischer Return to Technical Articles LIST Page Last check/edit:

Tuesday, August 15, 2023

1500

12.1

24

290

1600

1700

12.22

31

378

1700

12.16

35

426

2200

12.35

48

593

2500

13.4

54

724

2850

12.34

57

703

2850

13.36

48

641

3000

13.7

60

822

3000

14.09

34

480

3000

14.12

32

452

3000

13.4

62

831

3000

13.6

61

830

3000

13.85

59

817

3000

13.85

60

831

4000

13.87

65

902

5000

13.4

62

831

For all practical purposes, and I make no conclusions as to long term reliability, the 600 Omega (600 watt alternator from Jeff Lee of Emerald Island Company) produces enough electricity to keep most anyone happy. At the higher levels I feel are more important for battery recharge and life (~14 volts), it can produce ~450 to 500 watts at typical cruising RPM (and, even somewhat below). This alternator, in most any circumstances that are likely, such as in-city commuting and on-road cruising, will produce more than enough electricity, including that for just about any situation, at not much higher than idle RPM. This alternator will do quite well even in stop and go city traffic.

The EnDuralast system does not use a separate rectifying diode board or item, nor a separate voltage regulator. In the EnDuraLast system, these items are both combined into one finned metal case unit, that needs to be mounted someplace, and the unit is not going to fit on/at the Airhead motorcycle's original mounting points. The RR unit, as I will call it here, is a Ducati unit.

RPM

Current, Voltage

Watts

900

6 amperes

1000

7.5 amperes, 13.12 volts

98.3

1000

8 amperes

1200

12.5 amperes, 13.39 volts

167.4

1500

15 amperes

1600

16 amperes

1900

18 amperes, 14.24 volts

256.3

2050

20 amperes, 12.81 volts

256.2

26.5 amperes, 12.8 volts

339.2

At 1200 RPM, the output would be enough to maintain a good battery charge and have enough electricity to run the stock-equipped motorcycle. Even at 1000 RPM, the output would maintain the battery well-enough. Since I recommend that Airhead idle RPM be set for 1025 (target), there is no problem with this alternator's in-city output, at least with stock electricals. Note that the maximum output does not meet published advertised specifications for maximum output. Further, note that the output voltage SAGS as output current drain is increased, above 1900 RPM. I personally rate this alternator at approximately 260 watts. Compare the output to the stock 280 watt Bosch!

The EnDuraLast has more usable wattage output at low rpm, compared to the stock Bosch, or the 400 Omega. However, the 400 Omega has higher absolute maximum output wattage, and the Omega 450 and 600 have even higher output. Note also that, for the EnDuralast, the voltage at high watts output is not actually all that much different, and sometimes worse, than the stock 280 watt Bosch. Compare very carefully! The advantage of the EnDuraLast permanent magnet alternator is at low rpm ....but it does NOT have more wattage at its maximum output, compared to the stock Bosch, until the rpm is quite high.

In June, 2015, I tested another Permanent Magnet EnDuraLast alternator installation, this time in a 1995 R100RT. Installation was of the 'new method' of the type I had long recommended to Euro Motoelectrics; with some additional mounting improvements. The RR unit was mounted on the left rear down-tube frame member next to the battery. I made sure all connections, etc., were solid, proper heavy gauge, etc, before I load tested the Odyssey battery (yes, an Odyssey, which is a 'not recommended' type for the EnDuraLast), and then ran the battery down a few ampere-hours more, before doing tests. These were simple tests, with a digital voltmeter at the battery; and an ammeter in series with the RR unit's output by replacing the fuse with jumpers, which were nearly a foot long overall, and not of heavy enough gauge to give absolute maximum possible performance values but adequate for older installations, with some years on them, etc. These are real-world representative numbers; what you might expect. If large gauge wires were used, or a clamp-on/over meter, and a more discharged battery, particularly if not an Odyssey, I believe the output would have been slightly higher. NOTE that this installation proved out my previous work and suggestion that the RR unit be mounted next to or near the battery for slightly higher performance, due to temperature and shorter RR outer leads, versus longer input leads.

8 amperes output at 900 rpm.

10 amperes output at 1000 rpm (and, 12.42 volts).

From 1150 RPM and up, the output was sufficient to enable maintaining the battery at fully charged, if the motorcycle had stock electric drains.

13 amperes output at 1200 rpm.

17 amperes output at 1500 rpm.

17.5 amperes output at 1600 rpm.

18 amperes output at 1900 rpm.

21 amperes output at 2050 rpm.

I did a further test as the battery began to recharge, but still was not fully charged. That test was at 2500 rpm, and I got 19 amperes at 13.95 volts (265 watts)....and, after several minutes, noted the RR unit was getting fairly hot. This was with no forced air cooling. I did not try for an absolute maximum wattage output, which would have required discharging the battery again, and this time more considerably. I do not believe the output would be over 325 watts under any circumstances of practical use. That value is based on the battery terminal voltage to be at least 13.9.

1. The permanent magnet rotor in the EnDuraLast alternator has fan blades at the forward end. Due to the fan proximity to the BMW engine outer aluminum cover, the fan makes a small amount of whirring noise during operation, that varies with engine RPM. This has been remarked upon now and then, but is not annoying, unless you have 'just' noticed it.

2. The installation requires modifications to the motorcycle wiring system. This may or may not be of concern to you, during the installation.......or..........if contemplating a return to the stock wiring at some future date.

3. The exact reasons behind some RR failures are not known to me.

4. There may still be restrictions on the type of battery being used. Perhaps see latest available installation instructions.

Rev.

01/27/2008: Checked for clarity.

02/06/2009: Mention of the Omega 450.

09/16/2009: Update article for clarity, numerous places.

05/07/2011: Clarifications for comprehension, entire article.

09/17/2012: Minor updates. QR code added; Google ad layout changed.

2013: Remove language button, due to problems on some browsers.

10/22/2014: Minor updates; some commentary about real-world usage at equilibrium and slightly above, that I had not emphasized previously.

06/16/2015: Addendum

12/26/2015: Increase font size. Update meta-codes. Justify left for everything. Clarify a few things.

04/18/2016: Format & meta-codes. Add testing, 450 & 600 Omega type alternators, done 04/17. Re-write the article to improve clarity, less confusion.

04/19/2016: Clarify a few details between all the Omega alternators.

04/21/2016: Add testing schematic diagram and photo and information on Omega 400/450 and 600.

04/22/2016: Clarified the testing at below fully charged battery status, and why. Added commentary in 3 places regarding the Omega's, which now outshine

the EnDuraLast PM in many respects, add photo, etc.

06/14/2016: Update the article for clarity (in all sections) and add detailed testing information on the "600". 06/15: Note added on revising this year, and some minor clarifications of basic ideas near the beginning of the article. Minor corrections to notice at top, in early August.

08/07/2016: Add photo of 1995 stator.

11/24/2017: Re-do layout completely for readability, clarity, ease of use. Reduce excessive HTML. Reduce font changes. Improve layout. Cleaner and more distinct tables. Improve appearance and readability.

11/17/2020: Clarity improvements.

01/07/2021: SAME